Factory Service Manual For New Holland Tractor. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 638

Number: 87616423 — 01 — 2007

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Model

New Holland Tractor

TD60D

TD70D

TD80D

TD90D

TD95D

Contents

-GENERAL

General Instructions

Notes For Spare Parts

Notes For Equipment

Safety Rules

Consumables

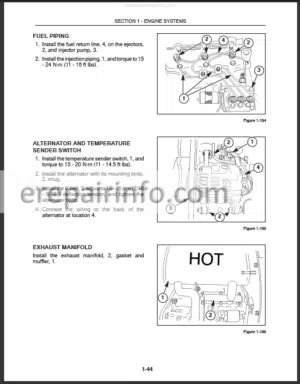

-ENGINE

General Specification

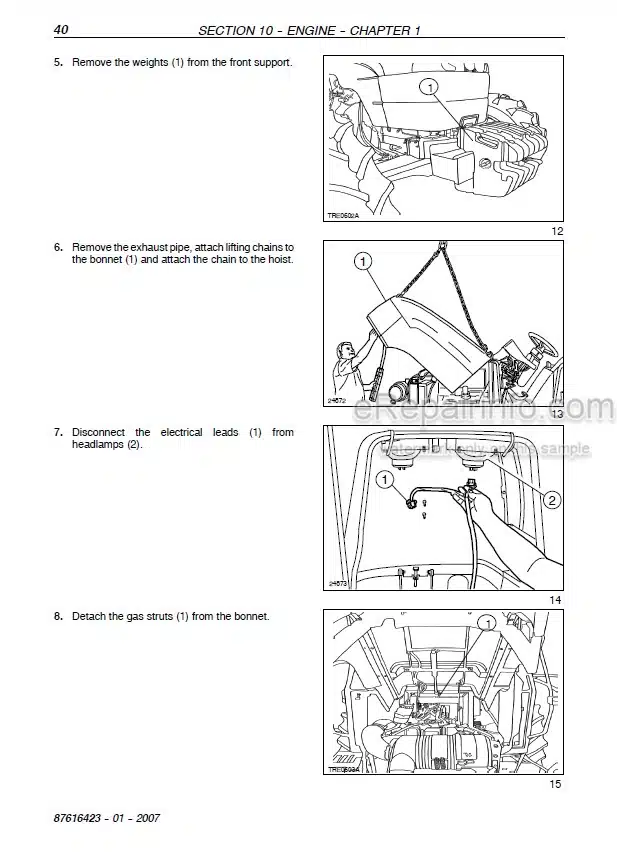

Engine Removal-Installation

Engine Bench Overhaul

Radiator Removal-Installation

Crankshaft Front Oil Seal Removal Installation

Coolant Pump Removal Installation

Cooling System Thermostat

Bosch Injection Pump Removal Installation

Injectors Removal Installation

Valve Clearance Adjustment

Coolant Pump Overhaul

Compression Test

-CLUTCH

General Specifications

Removal – Installation

Adjustment Of The Main And PTO Clutch Control Linkage

-GEARBOX

Mechanical Transmission (12×4)

Reverser (12×12)

Reverser and Creeper (20×12)

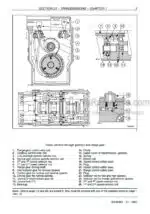

-TRANSMISSION OF MOTION

Main Specification

Torque Settings And Tools

Cross-Sectional Views

Transmission Shafts And Guard (Disassembly – Assembly)

Drive Gear Housing (Removal – Installation)

Drive Gear Housing Removed (Disassembly – Assembly)

-FRONT MECHANICAL TRANSMISSION

Main Data

Tightening Torques

Tools

Cross-Sectional Views

Description And Operation

Complete Front Axle Removal – Installation

Front Axle Removal – Installation

Steering Knuckle Bearing Pins Replacement

Stub Axle Adjustment

Wheel Hub Bearing Adjustment

Bevel Drive Adjustment

Front Axle Differential Overhaul

Front Axle Differential With LIM-Slip Overhaul

Front Axle Differential With No Spin Overhaul

Leading Drive Wheels Toe-In Check

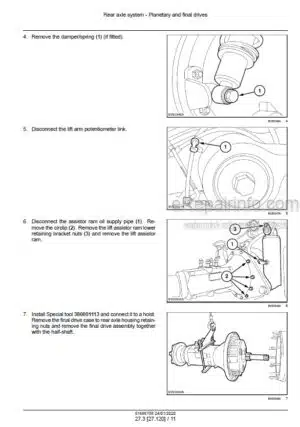

-REAR MECHANICAL TRANSMISSION

Main Data

Tightening Torques

Special Tools

Cross-Sectional Views

Description And Operation And Troubleshooting

Transmission-Gearbox Casing Removal-Installation

Transmission-Gearbox Casing Disassembly-Overhaul

Gearbox Driven Shaft End Float Adjustment

Differential Lock Engagement Sleeve Adjustment

Determining The Bevel Pinion Positioning Adjustment Ring

Adjusting The Taper Roller Bearings For The Bevel Pinion Shaft

Adjusting The Bearings And Checking The Backlash

Differential Pinion And Side Gear Backlash Adjustment

-POWER TAKE-OFF

Main Specification

Tools

Torque Settings

Sectional Drawings

Description And Operation

Troubleshooting

Removal – Refitting

Bench Overhaul

-BRAKES

Main data

Front Brake Assembly Mod TD60D And TD70D Removal And Refitting -Overhauling On The Bench

Service Brake Removal And Refitting

Removal-Refitting Of Front Brake Pumps

Bleeding Air From The Front Braking System

Adjusting Service Brake Pedals Travel

Parking Brake Travel Adjustment

-HYDRAULIC SYSTEMS

Rear Mechanical Hydraulic Lift

Open Centre System Auxiliary Control Valves

Trailer Brake Auxiliary Control Valve

-STEERING

Principal Data

Hydrostatic Steering Control Valve – Removal-Installation

Hydrostatic Steering Control Valve – Disassembly-Assembly

Hydrostatic Steering Control Valve – Bench Testing

Steering Cylinder (Two-Wheel Drive Axle) – Removal-Refitting

-FRONT AXLE AND WHEELS

Principal data

Removal-Refitting-Overhaul

Wheel hub disassembly-assembly

Stub axle overhaul

Checking wheel alignment

-AUXILIARY EQUIPMENT

Safety Instructions

Drying Recharging And Checking Cooling

Functional Testing Of Air Conditioning System

Receiver-Drier – Replacement

Condenser – Replacement

Compressor – Removal-Refitting

Compressor Drive Belt Tension Adjustment

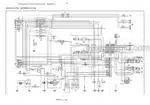

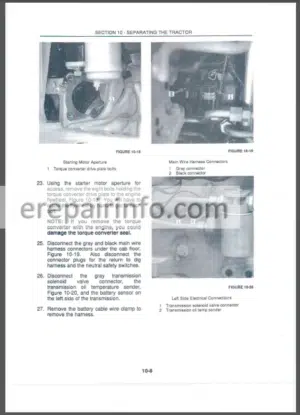

-ELECTRICAL SYSTEM

Instruments

Components

Starting System

Charging System

Battery

Electrical Circuits

-BODYWORK AND DRIVER POSITION

Disassembly–Assembly

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet