Factory Operators Manual For New Holland Tractor. Manual For Owners And Operators. It Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Description Of Possible Faults / Problems And Their Solution.

Format: PDF

Language: English

Pages: 306

Number: 87557824 (june 2006)

Bookmarks: Yes

Searchable: Yes

Model

New Holland Tractor

TL70A

TL80A

TL90A

TL100A

Contents

-INTRODUCTION AND SAFETY MEASURES

Communications For The User

Tractor Identification

Important Ecological Considerations

Always Work Safely

Working Safely

Safety Decals

Standard Symbols

Tractor Noise Level Information Sheet

-GENERAL INFORMATION, CONTROLS AND INSTRUMENTS

General Notes, Controls And Instruments

Before Using The Tractor

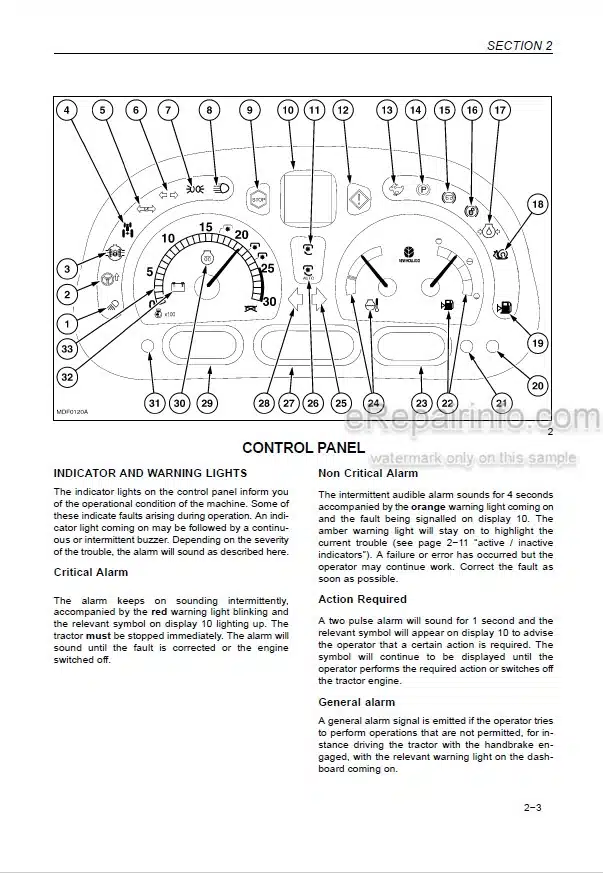

Control Panel

Control Panel

Operating Controls

Seat Adjustment

Cab

Air Conditioned Cab

Gearbox Transmission

Transmission With Range Gear – 1864 Mph (30 Km/H) (12F + 4R – Synchro Command)

Transmission With Range Gear And Shuttle – 1864 Mph (30 Km/H) (12F + 12R – Synchro Shuttle)

Transmission With Creeper And Shuttle – 1864 Mph (30 Km/H) (20F + 12R – Synchro Shuttle)

Transmission With Dual Command (2 Speed Power Shift) – 1864 Or 2485 Mph (30 Or 40 Km/H) (24F + 12R)

Transmission With Dual Command (2 Speed Power Shift) / Electro-Hydraulic Power-Shuttle 1864/2485 Mph) (30/40 Km/H (24F + 24R)

Fast Transmissions 2485 Mph (40 Km/H)

-FIELD OPERATION

Field Operation

Starting In Low Outside Temperature Conditions

Starter Key Switch

Starting With Grid Heater On Request

Electrohydraulically Controlled Four-Wheel Drive

Rear Mechanical Differential Lock (With Mechanical Control – Standard)

Braking System

Power Take-Off

Mechanically Operated Hydraulic Lift

Electronically Controlled Hydraulic Lift

Three-Point Linkage

Implement Connection Points

Auxiliary Remote Control Valves

Auxiliary Remote Control Valves (De Luxe Version)

Track Adjustment

Tyre Sizes

Tyre Combinations

Ballast

Permitted Maximum Weights

-LUBRICATION AND MAINTENANCE

Lubrication And Maintenance

Access For Inspection And Maintenance

Lubrication And Maintenance Table

Instrument Panel Warning Lights

Every 10 Hours Of Work

Every 50 Hours Of Work

Every 300 Hours Of Work

Every 600 Hours Of Work

Every 1200 Hours Or Every Year

Every 1200 Hours Or Every 2 Years

Every 1800 Hours Of Work

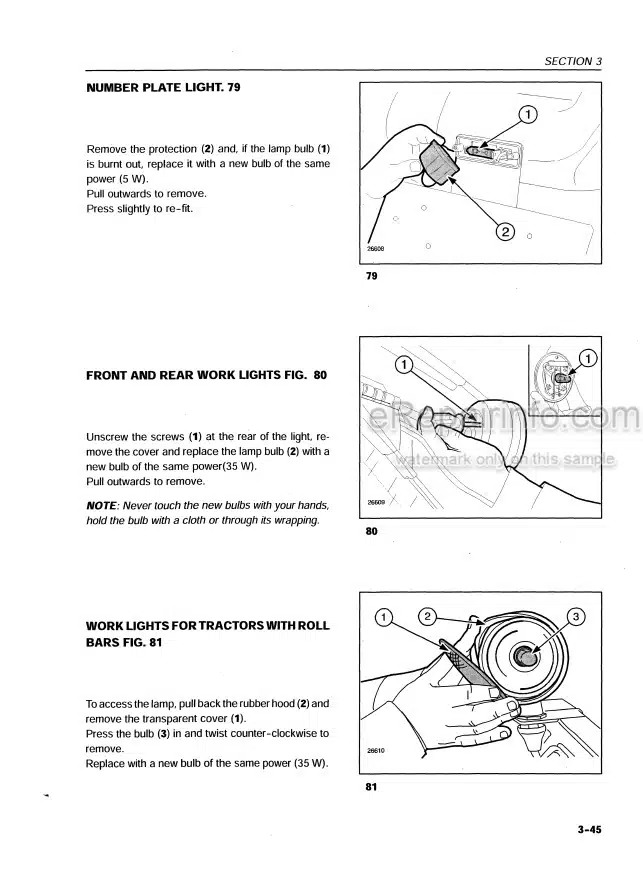

General Maintenance

Electrical System

Recommendations For Bodywork Maintenance

Consumables

-TROUBLESHOOTING

Engine

Electrical System

Hydraulic Circuit

Hydraulic Lift And 3-Point Linkage

Braking System

Cab

-VEHICLE STORAGE

Prolonged Tractor Inactivity

-ACCESSORIES

Quick Fit Implement Linkage

Towing Equipment

Fold-Down Roll Bar

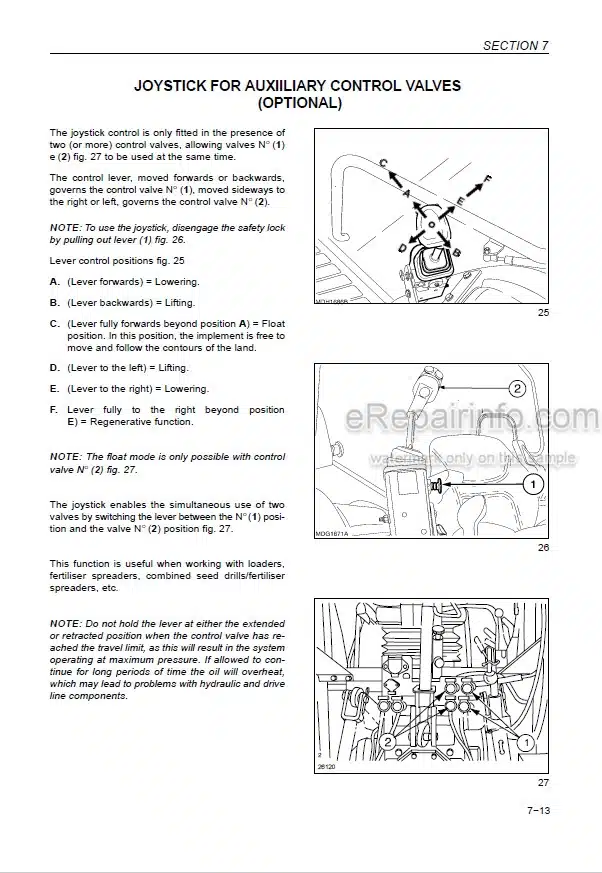

Joystick For Auxiliary Control Valves (Optional)

Front Loader Prearrangement

Control Valve For Trailer Hydraulic Brakes

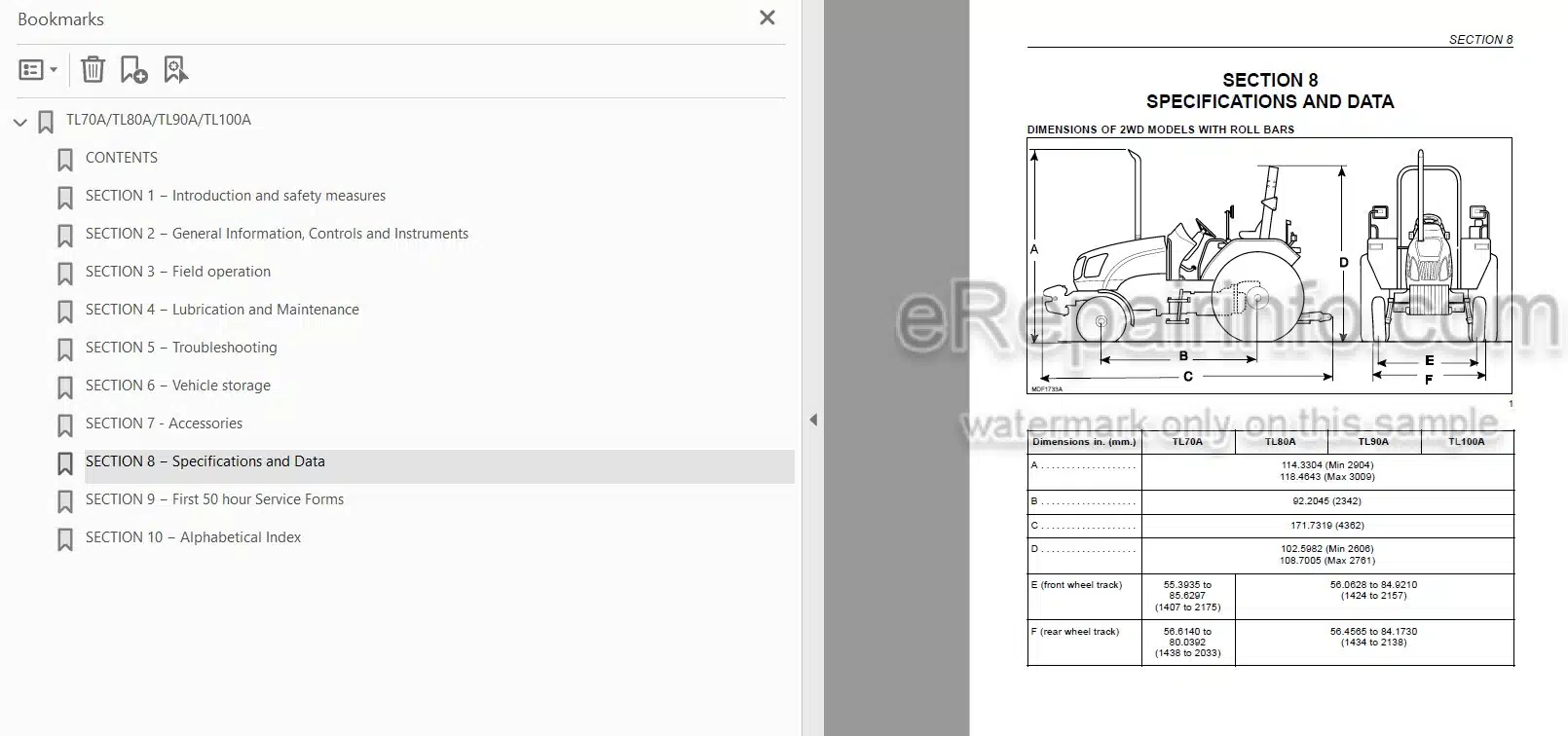

-SPECIFICATIONS AND DATA

-FIRST 50 HOUR SERVICE FORMS

-ALPHABETICAL INDEX

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet