Factory Service Repair Manual For New Holland TT60, TT75A Tractors. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 708

Bookmarks: Yes

Searchable: Yes

Number: 84154805

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

New Holland TT60A, TT75A

Contents

- General

General Instructions

Important Notice

Shimming

Rotating Shaft Seals

Orings

Sealers

Bearings

Spring Pins

Precautionary Notice

Equipment Notice

Spare Parts Notice

General Notices

Health And Safety

Health And Safety Precautions

General Workshop Toots And Equipment

Legal Aspects

Lubricants And Greases

Precautionary Statements

Safety

The Tractor

Driving The Tractor

Operating The Tractor

Operating The Pto

Servicing The Tractor

Diesel Fuel

Ecology And The Environment

Minimum Hardware Tightening Torques

General Dimensions

Federal Emissions Warranty

California Emission Control Warranty Statement

Universal Symbols

Safety Decals

Safety Decals

Instructional Decals - Engine

Engine Torque Specifications

Metric Beit Torque Specifications

Special Toots

Troubleshooting

Description arid OperabonEngine Components

Cylinder Head assembly

Camshaft Assembly

Cylinder Bloch Assembly

Crankshaft Assembly

Connecting Rode

Pistons

Manifolds

Timing Gears

Lubrication System

Cooling System

Fuel System

Fuel Shut Off (injection Pump)

tuft Pimp

Fuel Filters

Engine Preparation

Engine RemovalInstallation

Separating Engine from Transmission Hous>ng

Separating Front Axle from Engine

Engine Installation

Engine Compression Test

Test Procedure

test readings

Test Condition

Cylinder Head

Roper And Inspection

Injector Sleeves

Valve Settings

Valves

Valve Guides

Valve Springs

Tappets And Pushrods

Rocker Shall

Front Engine Caver

Timing Gear

Idler Gear

Fuel Pump Drive Gear

Fuel Iroction Pump Drive Gear

Camshaft Drive Gear

Hydraulic And Power Steering Pump Drive Gear

Inspection And Repair

Camshaft

Camshaft Drive Gear

Camshaft Bearings

Idler Gear Bushing

Camshaft Fuel Pump Drive Gear, Hydraulic And

Power Steering Dnvo Goals

Front Seal

Valve Timing

Adjustment

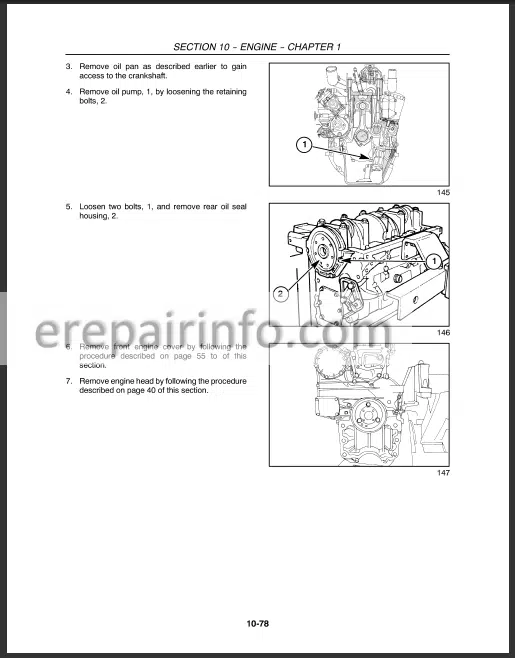

Oi Pan

Dynamo Balancer

Connecting Rods Bearings, Reasons And Rngs

Connecting Rod Alignment

Cylinder Block

Flywheel

Man Bannng And Crankshaft

Fuel System

Ar Cleaner

Service The Engine Air Cleaner Outer Element

Fuel Injection Pump

The Fuel injection Pump Tlmog With Pump On The Tractor

Fuel System Air Bleeding

Injector

Testing And Overhaul

Fuel Pump

Lubrication System

Oil Pump

Oil Filter

Oil Pressure Warning System

Engine Oil Consumption Diagnosing Procedure

Oil Consumption Test Procedure

Compression Test

Teet Heatings

Test Conclusion

Rework Instructions

Oil Consumption Tost Form

Cooling System Iis

Radiator

Removal

Report And Inspection

Thermostat

Water Pump

Water Temperature Gauge

Belt Tension Adjustment - Clutches

Clutch assembly

Cutch Plate

Longitudinal Section

Clutch Mechanical Release Control

Clutch Pedal

Pto Clutch Lever

Cross Shafts

Transmission Pto Release Bearing Assembly

Transmission Clutch Pedal FreeTravel And Adjustment

Adjusting Pto Clutch Linkage

Clutch Assembly

Release Fingers

Release Lever Height Adjustment

Important Points To Be Taken Into Account While Replacing Clutch - Transmission System

Precaution At Flange And Tool Ends

Reassembling Methods

Recommendations Regarding Lubrication

Shaft Seals

ORing

Adjusting Shims

Bearings

Sealing

Oil Drain

Sealants

Special Tools

Description And Operation

Transmission Internal Components

Drive Shaft Removal

Drive Shaft Installation

EndPlay Specification

Gear Rails

Special Tool Required

Range Gear (EpiCyclic) Assembly

Reverse Gears And Drive Shaft

Driven Gears And Drive Shaft

Checking Driven Gear Shaft Endplay

External Components Gear Shift Lever

Reverse Lever And Cover - Front Drive Axle

Front To Rear Axle Ratio

Front Axle

Steering Knuckle Pms And Bearings

Stub Axle Adjustment

Wheel Hub Bearing Adjustment

Bevel Drive Adjustments

Adjustment Of The Preload Of The Pinion Shaft Bearings

Determining The Thickness Of The Drive Pinion

Position Adjustment Shim

Ring/Pinion Adjustments

Adjustment Of The Ring Gear Bearings And Checking The

Backlash Between The Pinion And Ring Gear

Front Axle Differential

End Float Adjustment

Toe In Adjustment - Mechanical Rear Wheel Drive

Description And OperationMechanical Rear Wheel Drives

Differential Lock

Rear Wheel Drive Housing

Differential Unit

Pinion Shaft

Shift Rails

Adjustments And Settings

Bevel Drive Shaft Bearing Preload Adjustment

Bevel Pinion Shaft Depth Adjustment

Assembling The Bevel And Pinion Shaft

Differential Bearing Adjustment And Bevel Drive Backlash Check

Differential Pinion And Side Gear Backlash Adjustment

Adjustment Of Ring Gear Bearings - Power TakeOff

Sealants

Sectional View

Description And Operation

Power TakeOff

Adjustments

Pto Clutch

Pto Shaft Assembly

Pto Brake - Braking System

Metric Boll Torque Specifications

Sectional Views Brake Control Assembly

Description And Operation Brake System

Brake Pedals And External Linkages

Parking Brake Linkage

Brake Pedal Free Play Adjustment - Hydraulic Systems

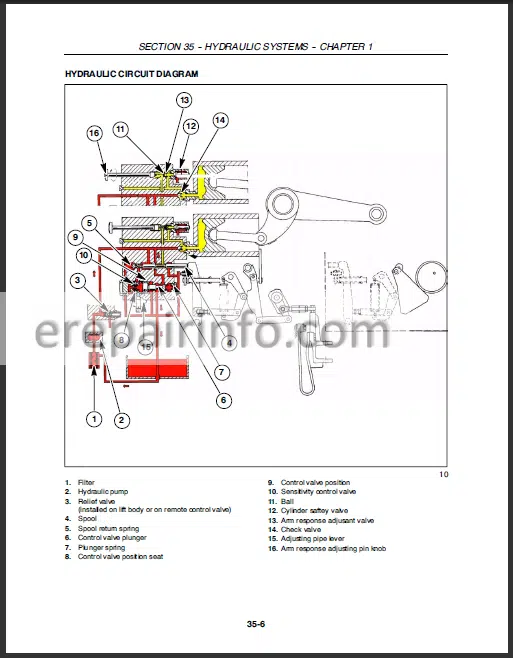

Introduction And Circuit Identification

Pump

Filter

Mechanical Hydraulic Lift Assembly

Remote Control Valve

Open Center Hydraulic Circuit And Mechanical Lift

Schematic View Of Hydraulic System

Hydraulic Circuit Diagram - Steering System

Steering Pump

Steering Test

Steering Retief Valve Pressure Test

Relief Valve AdjustmentAll Models

Description And Operation

Operation

StraightAhead Driving

Rh Steer

Lh Steer

Emergency Hydraulic Steer (C Sed Ses)

Power Cylinder Safety And Make Up Valves (N)

Hydrostatic Steering Reservoir

Inspection And Cleaning

Steering Motor

Inspection And Replacement

Lubrication

Assembly Pattern For Standard Bearing

Installation Of ORing

Installation Of Lip Seal - Front Axle

Front Axle Support

Stub Assembly

Troubleshooting

Description And Operation

Front Axle Assembly

Front Wheel Hub

Spindle Assembly

Front Wheel Setting Tests

Wheel Camber Test

Front Wheel ToeIn Test - Electrical System

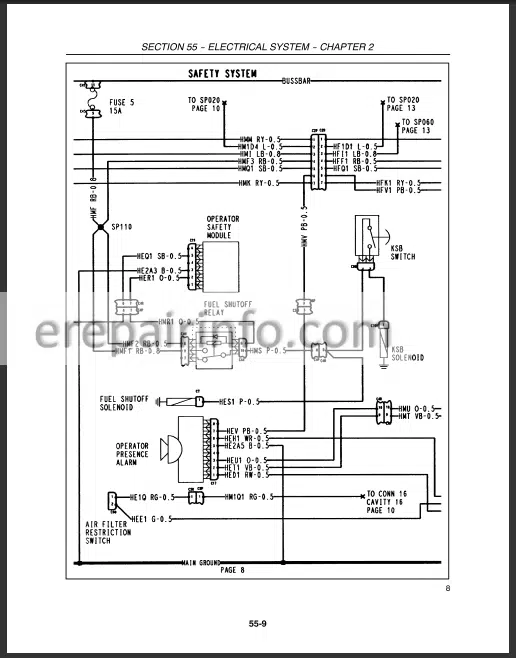

Description Of Electrical System

Component Location And Function

Wiring Harnesses

Grounds

Battery And Fuses

Battery

Description

Checking The Battery Electrolyte Level

Fuse Block

Fuse Replacement

Fuse Identification

Fusible Link

Electrical System Components — Description And Testing

Key Switch

Key Switch Terminals

Testing

Light Switch

Description

Terminal Identification

Light Switch

Testing

Hazard Light Switch

Turn Signal Switch

Transmission Range Safety Switch

Pto Safety Switch

Park Brake Safety Switch

Seat Safety Switch

Transmission Clutch Safety Switch

Relays

Description And Location

Testing (Neutral Start)

Testing Micro Relays (Fuel Shutoff, Pto Safety Stan

Hazard Flasher Cutoff)

Hazard FlasherTurn Signal Control Module

Operator Safety Module

Description And Location

Park Brake Safety Alarm (Buzzer)

Engine Sensors

Engine Oil Pressure Sender

Engine Coolant Temperature Sender

Ksb Temperature Switch

Ax Filter Restriction Switch

Fuel Level Sender

Lighting

Head Lamp

Bulb Replacement

Turn/Position Lights/Flasher

Bulb Sizes - Bodywork

Engine Hood Panel Assembly

Rear Wheel Fenders

Roll Over Protection (Rops) Bar

Battery

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet