Factory Disassembly And Assembly For Perkins Industrial Engine. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly Engine.

Format: PDF

Language: English

Pages: 140

Number: KENR6247 (may 2007)

Searchable: Yes

Model

Perkins 1104D (Mech) Industrial Engine

NK

NL

NM

Contents

-DISASSEMBLY AND ASSEMBLY

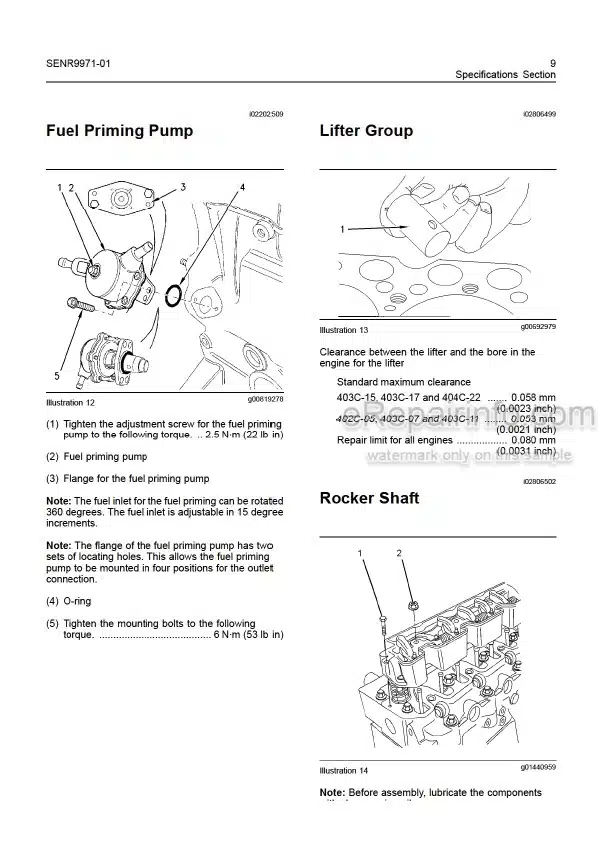

Fuel Priming Pump and Fuel Filter Base – Remove and Install

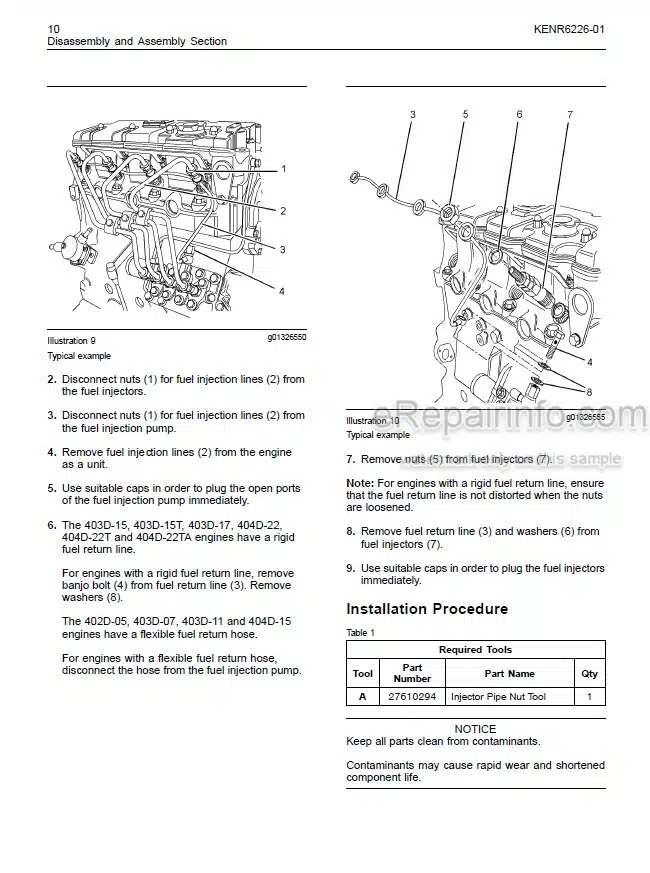

Fuel Injection Lines – Remove and Install

Fuel Injector Cover – Remove and Install

Fuel Injection Pump – Remove

Fuel Injection Pump – Install

Fuel Injection Pump Gear – Remove

Fuel Injection Pump Gear – Install

Fuel Injector – Remove

Fuel Injector – Install

Turbocharger – Remove

Turbocharger – Install

Exhaust Manifold – Remove and Install

Exhaust Elbow – Remove and Install

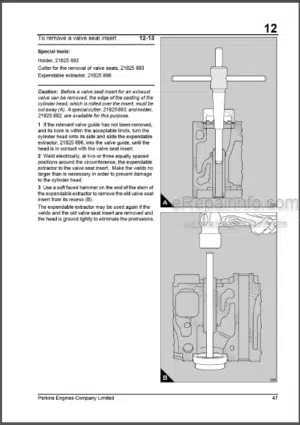

Inlet and Exhaust Valve Springs – Remove and Install

Inlet and Exhaust Valves – Remove and Install

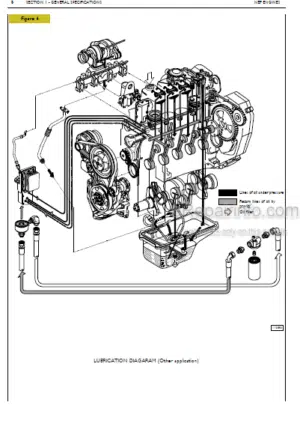

Engine Oil Filter Base – Remove and Install

Engine Oil Cooler – Remove

Engine Oil Cooler – Install

Engine Oil Relief Valve – Remove and Install (Engines Without a Balancer Unit)

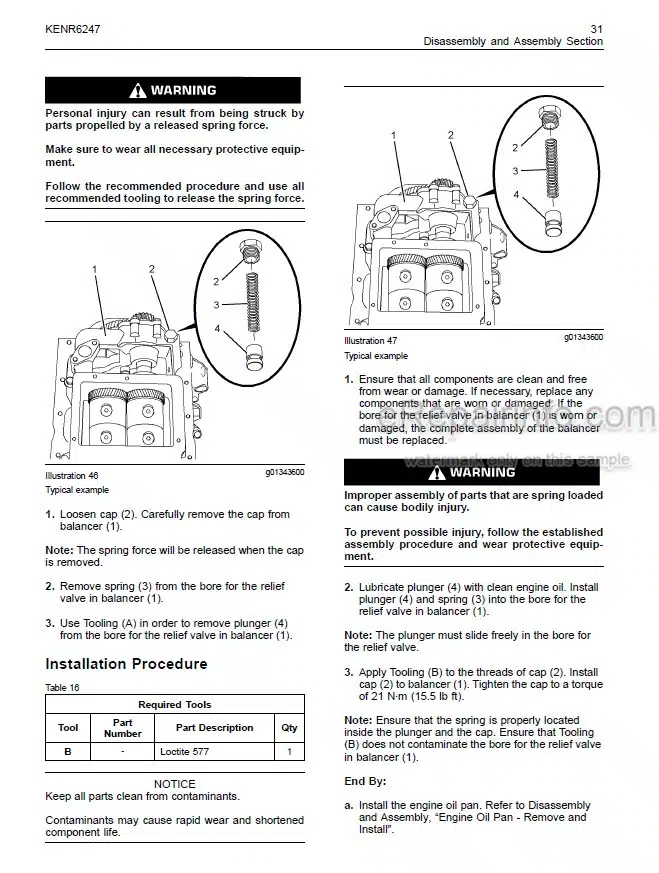

Engine Oil Relief Valve – Remove and Install (Engines with a Balancer Unit)

Engine Oil Pump – Remove and Install (Engines Without a Balancer Unit)

Water Pump – Remove

Water Pump – Install

Water Temperature Regulator – Remove and Install

Flywheel – Remove

Flywheel – Install

Crankshaft Rear Seal – Remove

Crankshaft Rear Seal – Install

Flywheel Housing – Remove and Install

Crankshaft Pulley – Remove and Install (Engines With an Automatic Belt Tensioner)

Crankshaft Pulley – Remove and Install (Engines Without an Automatic Belt Tensioner)

Crankshaft Front Seal – Remove and Install

Crankshaft Wear Sleeve (Front) – Remove and Install

Front Cover – Remove and Install

Gear Group (Front) – Remove and Install

Idler Gear – Remove

Idler Gear – Install

Housing (Front) – Remove

Housing (Front) – Install

Accessory Drive – Remove and Install

Crankcase Breather – Remove and Install (Turbocharged Engines with Unfiltered Breather)

Crankcase Breather – Remove and Install (Turbocharged Engines with Filtered Breather)

Crankcase Breather – Remove and Install (Naturally Aspirated Engines)

Valve Mechanism Cover – Remove and Install

Rocker Shaft and Pushrod – Remove

Rocker Shaft – Disassemble

Rocker Shaft – Assemble

Rocker Shaft and Pushrod – Install

Cylinder Head – Remove

Cylinder Head – Install

Lifter Group – Remove and Install

Camshaft – Remove and Install

Camshaft Gear – Remove and Install

Camshaft Bearings – Remove and Install

Engine Oil Pan – Remove and Install (Aluminum and Pressed Steel Oil Pans)

Engine Oil Pan – Remove and Install (Cast Iron Oil Pan)

Balancer – Remove

Balancer – Install

Piston Cooling Jets – Remove and Install

Pistons and Connecting Rods – Remove

Pistons and Connecting Rods – Disassemble

Pistons and Connecting Rods – Assemble

Pistons and Connecting Rods – Install

Connecting Rod Bearings – Remove (Connecting rods in position)

Connecting Rod Bearings – Install (Connecting rods in position)

Crankshaft Main Bearings – Remove and Install (Crankshaft in position)

Crankshaft – Remove

Crankshaft – Install

Crankshaft Gear – Remove and Install

Bearing Clearance – Check

Glow Plugs – Remove and Install

V-Belts – Remove and Install (Engines Without an Automatic Belt Tensioner )

Alternator Belt – Remove and Install (Engines With an Automatic Belt Tensioner)

Fan – Remove and Install

Fan Drive – Remove and Install

Alternator – Remove (Engines With an Automatic Belt Tensioner)

Alternator – Remove (Engines Without an Automatic Belt Tensioner)

Alternator – Install (Engines With an Automatic Belt Tensioner)

Alternator – Install (Engines Without an Automatic Belt Tensioner)

Electric Starting Motor – Remove and Install

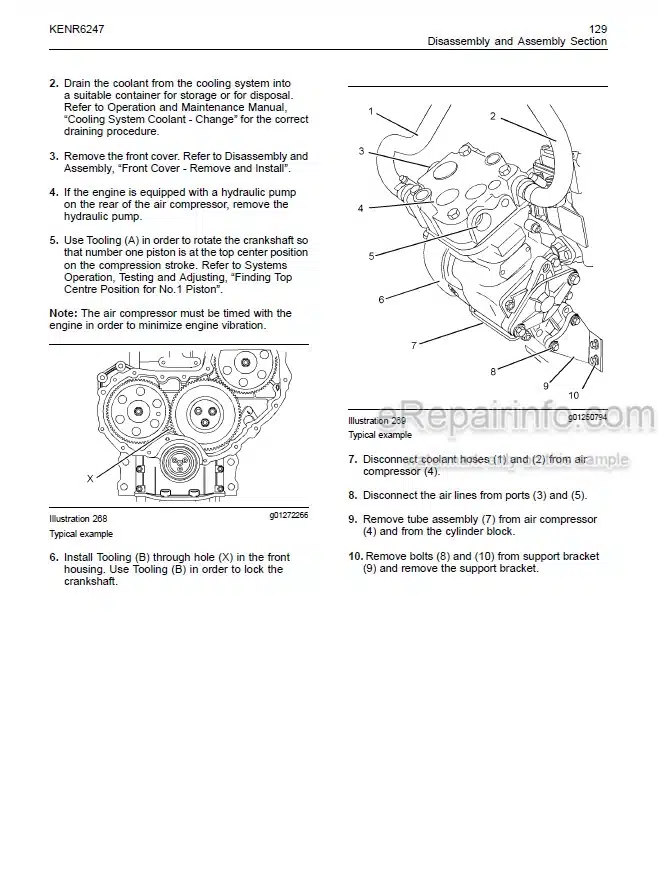

Air Compressor – Remove and Install

Vacuum Pump – Remove and Install

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet