Factory Service Repair Manual For Terex PT-100 Rubber Track Loader. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 94

Bookmarks: Yes

Searchable: Yes

Hydraulic Diagrams: Yes

Model

Terex

PT-100 FORESTRY

Contents

- – Product Safety

Chapter Overview

Basic Precautions

Safety Labels…

Personal Protective Equipment

Entering and Exiting

Lifting

Hot Fluids and Components

Corrosion Inhibitor

Batteries

Pressurized Items

Repair

Attachments

Machine Labels and Decals

Product ID Number

Safety Label Examples - – Technical Specifications

Specifications

Engine

Transmission

Drive Motors

Control Handles

Auxiliary Pump

Loader Valve

Cooler

Critical Torque Specifications - – Circuit Diagrams

Chapter Overview

Hydraulic Charge Circuit

Hydraulic Auxiliary Circuit

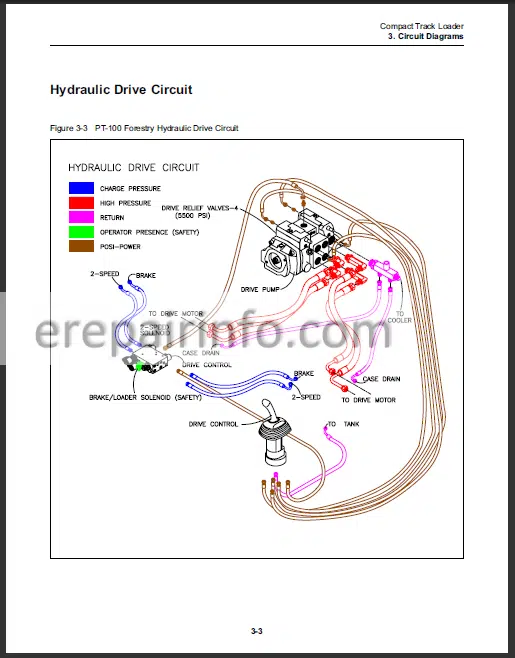

Hydraulic Drive Circuit

Lift Arm Control Valve

Hyd Pilot Gen Block

Electrical Attachment Outlet - – Machine Controls and Instrumentation

Chapter Overview

Machine Controls

Loader Control

Drive Control

Throttle

Instrumentation

Switches - – Operator Enclosure Disassembly

and Assembly

Chapter Overview

Personal Safety

Machine Preparation

Operator Enclosure Disassembly and Assembly

Procedures

Gauge Panel Removal and Installation

Gauge Panel Removal

Gauge Panel Installation

Ignition Switch Removal and Installation

Ignition Switch Removal

Ignition Switch Installation

Gauge Removal and Installation

Gauge Removal

Gauge Installation

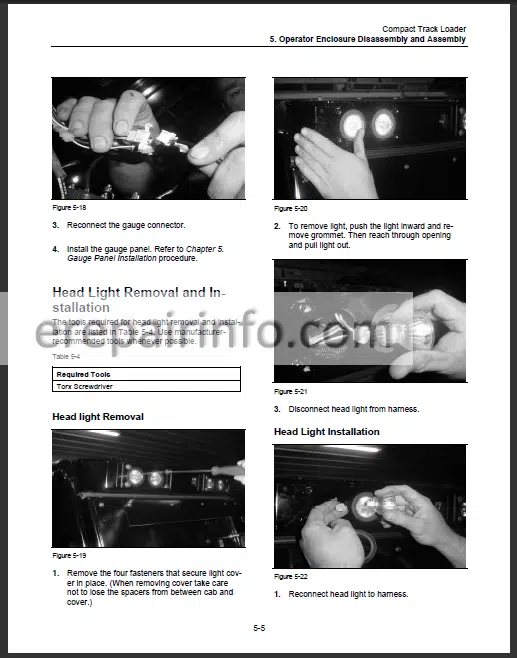

Head light Removal and Installation

Head Light Removal

Head light Installation - – Fuel Tank Disassembly and Assembly

Chapter Overview

Personal Safety

Machine Preparation

Disassembly and Assembly Procedures

Fuel Sending Unit Removal & Installation

Fuel Sending Unit Removal

Fuel Sending unit Installation

Fuel Tank Removal

Fuel Tank Installation - – Radiator/Oil Cooler Disassembly and Assembly

Chapter Overview

Personal Safety

Machine Preparation

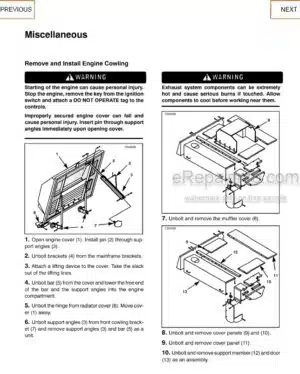

Radiator/Oil Cooler Disassembly and Assembly

Procedures

Fan Guard Removal and Installation

Fan Guard Removal

Fan Guard Installation

Fan Removal

Fan Installation

Radiator/Cooler Removal

Radiator/Cooler Installation

Reversible Fan Compressor and Control Box

Removal…

Reversible Fan Compressor and Control Box

Installation… - – Loader/Transmission Controls Disassembly and Assembly

Chapter Overview

Personal Safety

Machine Preparation

Loader/Transmission Controls Disassembly and

Assembly Procedures

Joystick Removal and Installation

Joystick Removal

Joystick Installation

Loader Float Magnet Removal and Installation

Loader Float Magnet Removal

Loader Float Magnet Installation

Rubber Track Loader

Table of Contents - – Hydrostatic & Aux Pump Disassembly and Assembly

Chapter Overview

Personal Safety

Machine Preparation

Hydrostatic & Hydraulic Pump Disassembly

and Assembly Procedures

Charge Pump Removal

Auxiliary Pump Removal

Auxiliary Pump Installation

Tandem Pump Removal

Tandem Pump Installation

Hydraulic Reservoir Clean out - – Undercarriage Disassembly and Assembly

Chapter Overview

Personal Safety

Machine Preparation

Undercarriage Disassembly and Assembly

Procedures

Sprocket Removal and installation

Sprocket Removal

Sprocket Installation

Drive Motor Removal

Drive Motor Installation

Wheel Replacement

Wheel Installation…

Wheel Keeper Plates… - – Maintenance

Chapter Overview

Personal Safety

Air Cleaner

Grease Fittings

Undercarriages

Track Tension

Drive Sprocket Rollers

TiltUp Canopy

Jacking Procedure

Lift Arm Brace

Track Removal

Track Installation

Engine Oil & Filter

Engine Oil Specifications

Engine Oil Level Check

Hydraulic Fluid & Filter

Fuel Filter

Case Drain Filter

Hydraulic Reservoir (Cleanout)

Water Separator

Fuse Panel

Drive Belt Tension Check

Drive Belt Tension Adjustment

Drive Belt Removal

Drive Belt Installation

Radiator/Oil Cooler Cleaning

Chassis & Engine Cleaning

Extreme Conditions

Cooler Air Flow Test

Cab Filtration

Fan Cleaning

Maintenance Schedule - – Lubricant & Fuel Specifications

Specifications - – Troubleshooting

Chapter Overview

Personal Safety

Machine Preparation

Preliminary Checkout

Visual Inspection

Troubleshooting Scenarios - – Hydraulic Pressure (Check & Adjustment)

Chapter Overview

Personal Safety

Charge Pressure Check & Adjustment

Auxiliary Pressure Check & Adjustment

High Flow Troubleshooting

Low Flow Troubleshooting

Lift Arm Pressure Check

Drive Pressure Check & Troubleshooting

PosiPower Pressure Check & Adjustment - – Hydraulic Cylinder & Loader Valve

Chapter Overview

Personal Safety

Disassembly & Assembly

Hydraulic Cylinder Disassembly

Hydraulic Cylinder Assembly

Loader Valve Disassembly

Loader Valve Assembly

What you get

You will receive a PDF file with high-quality manual(s) on your email immediately after the payment.

Reviews

There are no reviews yet