Factory Service Shop Manual For Terex TXC175 LC1. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 652

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Terex TXC175 LC1

Contents

- – Safety

To the Operator of a TEREX Excavator

General Safety Essentials

Location of Safety Labels

Summary of Safety Precautions for Lifting in Digging Mode

Unauthorized Modifications

General Hazard Information

Before Starting Engine

Machine Operation

Maintenance

Battery

Towing

Shipping and Transportation

Lifting With Sling

Track Excavator Safety - – Specifications

General Description

Component Locations

General Dimensions

Working Range

General Specifications

Engine Performance Curves (Per DIN 6270 Standard)

Approximate Weight of Workload Materials

Performance Tests

Excavator Performance Standards

Test Conditions

Travel Speed and Travel Motor Balance (Steering Deviation) Tests

Swing Speed and Deceleration Force Test

Cylinder Performance Tests - – General Maintenance

Welding Precautions and Guidelines

Hydraulic System – General Precautions

Maintenance Service and Repair Procedure

General Precautions

Hydraulic System Cleanliness and Oil Leaks

Maintenance Precautions for Hydraulic System Service

Oil Leakage Precautions

Cleaning and Inspection

General Guidelines

Bearing inspection

General Maintenance Procedures

Standard Torques - – Upper Structure

Removal

Installation

Cab

Counterweight

Fuel Tank

Fuel Transfer Pump

Swing Bearing

Swing Reduction Gearbox - – Lower Structure and Chassis

Track Tension

Cleaning and Inspection (Wear Limits and Tolerances)

Track Shoes and Links

Parts List

Track Removal

Track Installation

Front Idler Roller

Front Idler Roller Disassembly

Front Idler Roller Reassembly

Lower Roller

Lower Roller Removal

Lower Roller Disassembly

Lower Roller Reassembly

Lower Roller Installation

Upper Roller

Parts List

Upper Roller Removal

Upper Roller Disassembly

Upper Roller Reassembly

Track Spring and Track Adjusting Cylinder

Parts List

Track Assembly - – Engine and Drive Train

Refrigerant Circulation

Control Panel

Control Specifications

Temperature Level Control and Display

Air Discharge According to Path Selection

Air-conditioning System Circuit Diagram

Troubleshooting

Weight of R134a Gas Used In Machines

Refrigerant System Repairs

Refrigerant Safe Handling Procedures

Repair and Replacement Procedure

Refrigerant Recovery

Vacuuming Refrigerant System

Leakage Check

Refrigerant Charging

Inspecting System For Leakage

Air-Conditioner

Drive Coupling (Main Pump) - – Hydraulics

Hydraulic System – General Notes

Hydraulic Schematic

General Notes

Operation of Working Components

Boom Operating Circuit

Boom Up Circuit

Boom Down Circuit

Arm Operating Circuit

Arm Crowd Circuit

Arm Dump Circuit

Bucket Operating Circuit

Bucket Crowd Circuit

Bucket Dump Circuit

Swing Operating Circuit

Right Swing Operating Circuit

Left Swing Operating Circuit

Swing Relief Valve and Make-up Valve

Travel Operating Circuit

Forward Travel Circuit

Reverse Travel Circuit

Procedural Troubleshooting Baseline Recommendations

Initial Checks and Tests to Establish Operating

Condition of the Excavator

Pilot Pressure

Adjustment and Testing

Power Mode Valve

Current Signal and Hydraulic Pressure Adjustments

Boom/Front Priority Valve

Control Valve Pressure and Current Adjustments

Pressure Up Valve

Checks and Adjustments

Hydraulic System Troubleshooting, Testing and Adjustment

Pump Input Power Control

Pump Regulator Adjustment

Flow Meter and Flow Meter Kit Installation and Testing

Swing System Troubleshooting

Precautions/Initial Checks

Swing Relief Valve Checking and Adjustment

Troubleshooting – Swing Gearbox

Troubleshooting – Hydraulic Problems

Troubleshooting – Control Valve

Troubleshooting – Travel Control Valve

Troubleshooting – Joystick Control Valve

Hydraulic System Troubleshooting, Testing and Adjustment

Accumulator

Center Joint (Swivel)

Cylinders

Swing Motor

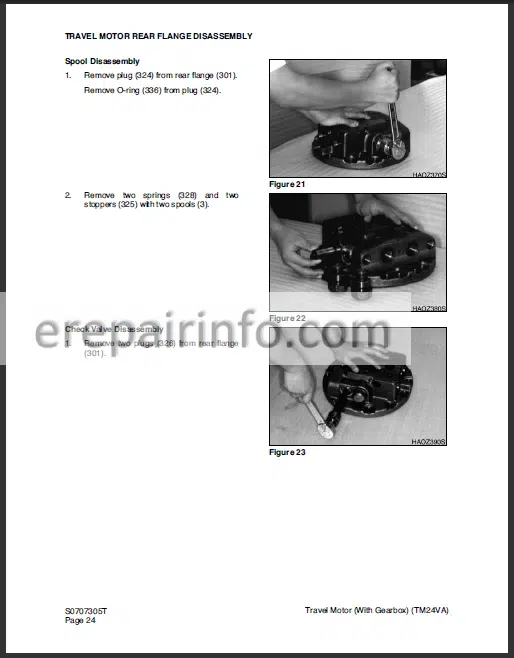

Travel Motor (With Gearbox)

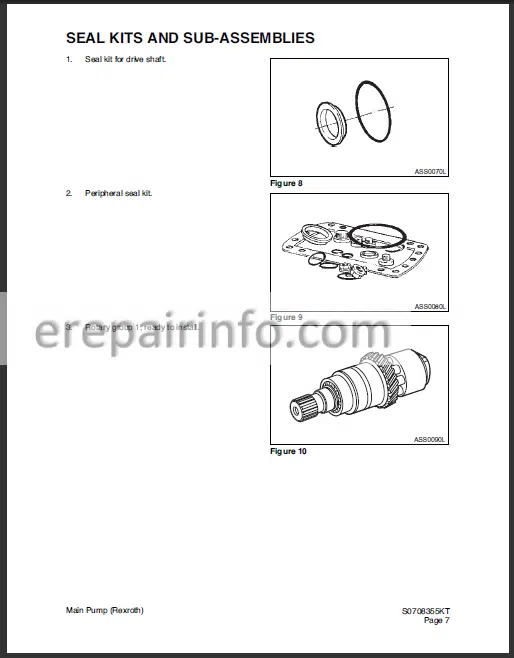

Main Pump (Rexroth)

Main Control Valve

Pilot Control Valve (Work Lever / Joystick)

Travel Control Valve (With Damper)

Hydraulic Schematic - – Electrical System

Troubleshooting – Electrical System

Overview

Electric Supply System

Engine Starting Circuit

Operation During Start Process

Operation After Start Process

Engine Preheating System

Engine Stop System

Charging System

Monitoring System

Instrument Panel

Monitoring System Schematic

Operation

Instruments

Warning and Indicator Lights

Initial Operation

Mode Select Switch

Graphic Information Area Display

Overview

Main Menus for the Graphic Display Area

Menu Selection Buttons

Main Menu

Language setting

Time Setting

Filter/Oil information

Special Menu

Entering/Accessing and Exiting/Escaping Menus

Special Menu Selections

Electronic Hydraulic Control System (e-EPOS)

Control System Schematic

Power Mode Control

Electrical System Operation

Power Mode Control – Circuit Diagram

Work Mode Control

Operation

Work Mode Control – Circuit Diagram

Engine Control System

Engine Control Motor

Engine Control Dial

Engine Control Circuit Diagram

Automatic Deceleration Control (Auto Idle Control)

Engine Overheat Protection System

Power Boost Mode

Operation

Power Boost Control – Circuit Diagram

Automatic Travel Speed Control

Automatic Travel Speed Control – Circuit Diagram

Engine Control Device – Adjustment

Self-diagnostic Function

e-EPOS Controller

Engine Throttle Controller

Wiper System

Wiper Circuit

Wiper Operation

Window Washer Operation

Lighting System

Lighting System Circuit Diagram

Kind of Light

Operation

Overload Warning Device

Overload Warning Device Circuit Diagram

Electrical Schematic - – Attachments

Front Attachment Pin Specifications

Front Attachment – Removal and Installation

Arm Removal Procedure

Boom Removal Procedure

Installation

Arm Installation Procedure

Boom Installation Procedure

Start-up Procedures

Boom and Arm

Bucket

What you get

You will receive a PDF file with high-quality manual(s) on your email immediately after the payment.

Reviews

There are no reviews yet