Factory Service Manual For Tigercat Loader. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 220

Number: 29467A (february 2010)

Bookmarks

Searchable

Wiring Diagrams

Hydraulic Diagrams

Model

Tigercat Loader

234

Contents

INTRODUCTION

NON-APPROVED FIELD PRODUCT CHANGES

-SAFETY

Battery Disconnect Switch

Battery Safety

Cooling System

Exhaust Fumes

Fire Prevention

First Aid

Fluid Injection Injury

Fluid Leaks

Grease Injection Injury

Lightning Safety Awareness

Loose Clothing Hazard

Protective Clothing

Safe Removal Of Counterbalance And Check Cartridge

Safety Labels

Safety Precautions, General

Safety Precautions, Operating

Safety Precautions, Servicing

Safety Symbols

Signal Words

Working With Oil

-LUBRICATION & MAINTENANCE

Air Cleaner

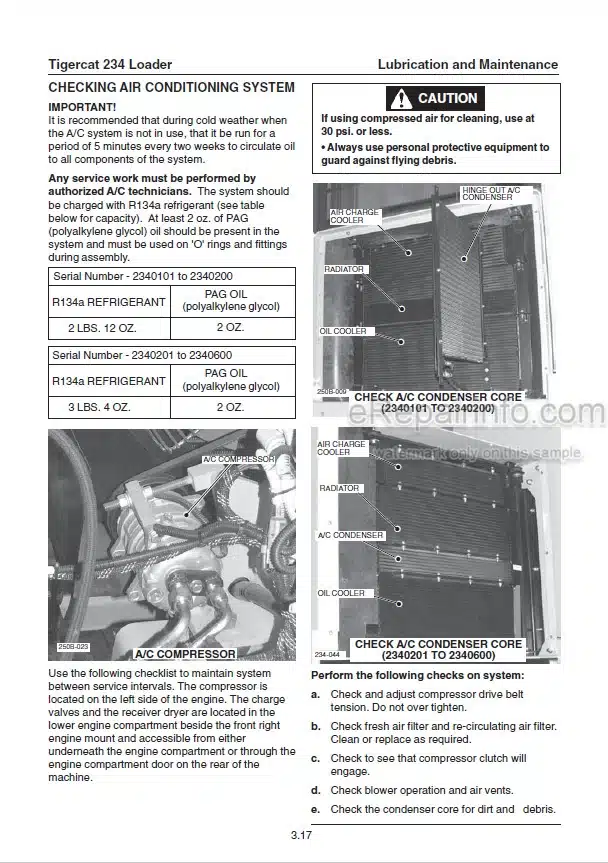

Air Conditioning

Approved Hydraulic Oils

Blink Codes

Case Drain Strainer

Emergency Exits, Check Monthly

Filter Restriction Indicator

Fire Prevention

First 125 Hour Inspection And Service

Hydraulic Oil Return Filters

Lubrication And Service Points

New Machine Maintenance

Oil Lost From Leakage

Oil Sample Collection Procedures

Oil Sampling Program

PAG Oil

Pilot Pressure Filter

Pre-Delivery Inspection

Pressure Settings

Preventive Maintenance Schedule

Refrigerant

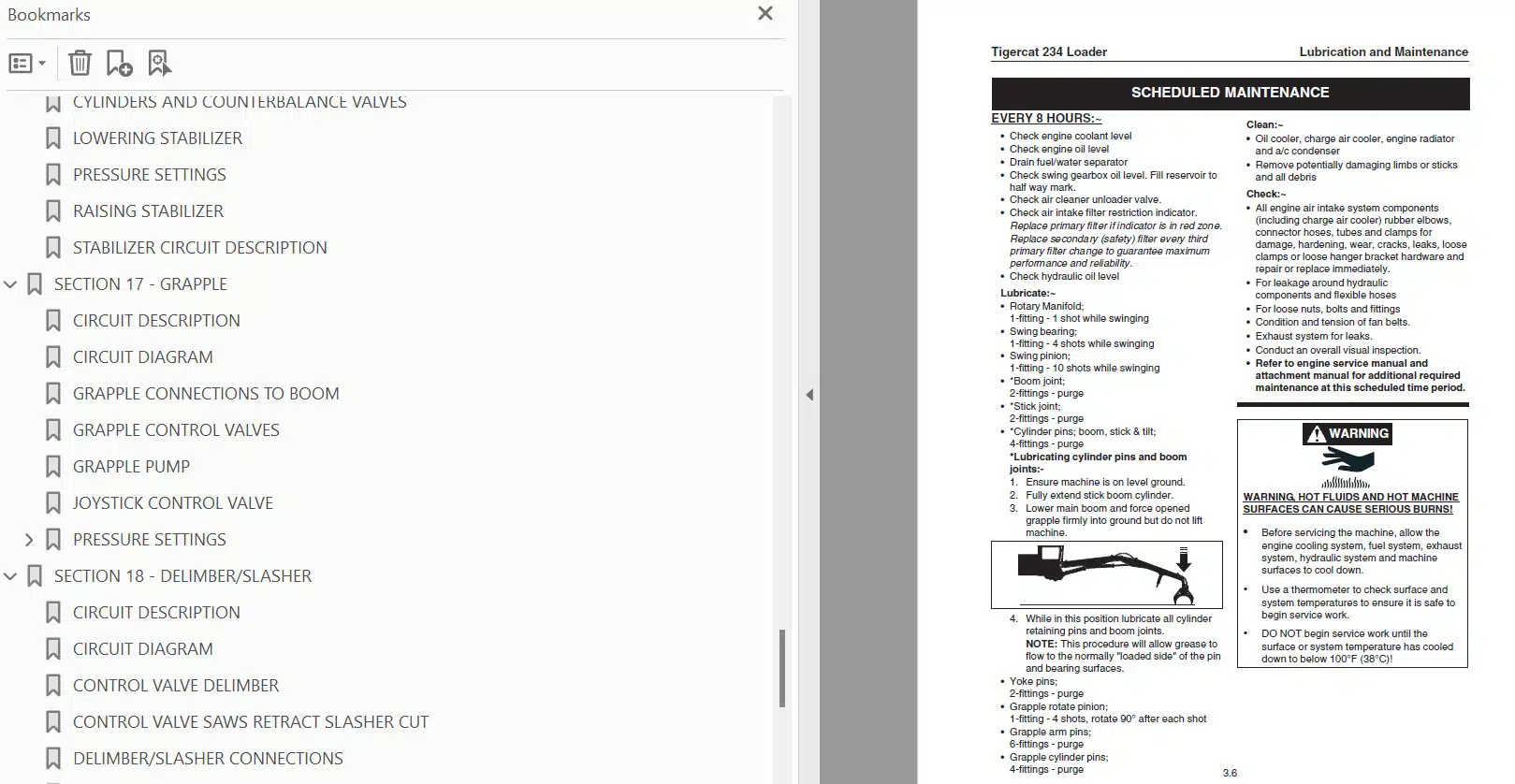

Scheduled Maintenance

Torque Chart

Torque, Fluid Connections

Torque Specifications – General

Weights Of Commercial Wood

-HYDRAULIC SYSTEM

Circuit Diagram

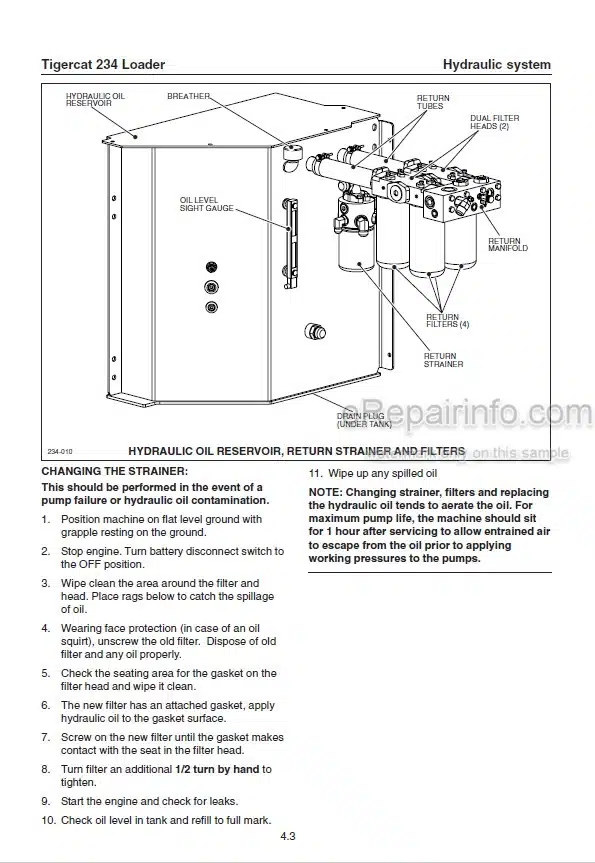

Hydraulic Oil Reservoir

Hydraulic Pumps

Hydraulic System Operation

Load Sensing

Main Control Valve

Main Pump Por Valve Setting

Por Valve Setting

Pressure Limiting Control

Strainer

-PILOT SYSTEM

Circuit Diagram

Electrical Circuit

Pilot System Components

Pressure Settings

-ELECTRICAL, GAUGES & ALARMS

Alternator

Battery Compartment

Battery Disconnect – Switch

Cab Wiring And Electrical Component Locations

Canbus Troubleshooting

Display Module

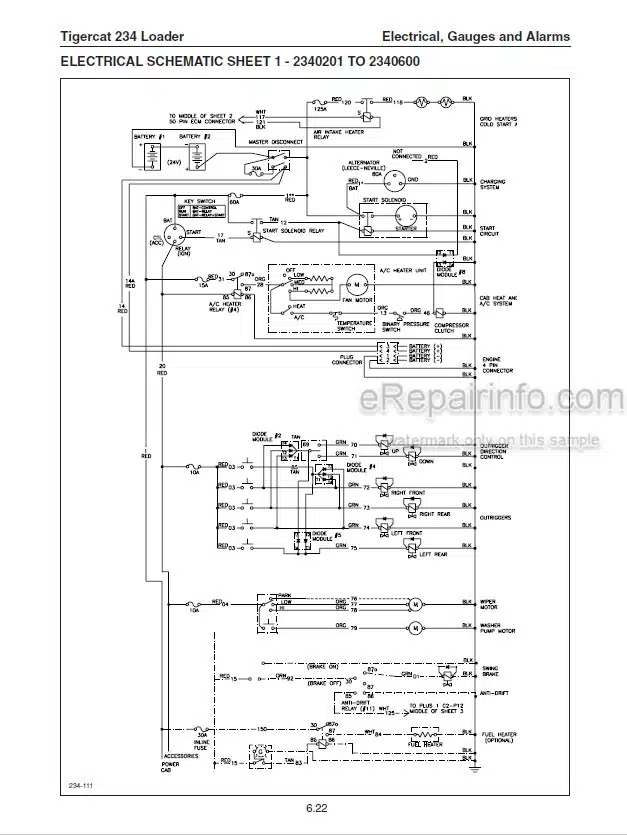

Electrical Schematic

Electrical System

Fuse And Relays

Gauges And Alarms

Gauges And Warning Lights

Instrument Panel Wiring Diagram

Saw Flow Control Potentiometers

Sensor Locations

Warning Lights

Wiring Diagram

-ENGINE START AND STOP

Circuit Description

Engine Start Circuit

Start Circuit Diagrams

-ENGINE ANTI-STALL

Anti-Stall System Components

Auto Idle Down

Blink Codes

Electrical Schematic – Plus 1 Control

Electronic Controller Blink Codes

Fault Finding Procedure ~ Anti-Stall Quick Check

Fault Finding Procedures, Additional

Horsepower Limiting Control

Hydraulic Pumps

Load Sense; Set Margin Pressure See Section 4

Plus 1 Control Module Connector Pin Assignment

Set Pilot Pressure See Section 5

Verify Anti-Stall Setting See Section 4

-BOOM

Circuit Description

Circuit Diagram

Control Valves

Filters

Hoist Valve Relief Valve Settings

Pressure Settings

Stick Valve Relief Valve Settings

-SWING

Circuit Diagram

Gearbox, Swing Drive

Hydrostatic Drive Motor

Pressure Settings

Swing Bearing

Swing Motor

Swing Pump

-STABILIZERS

Circuit Components

Control Valve

Counterbalance And Check Cartridges, Removal

Counterbalance Valves

Cylinders And Counterbalance Valves

Lowering Stabilizer

Pressure Settings

Raising Stabilizer

Stabilizer Circuit Description

-GRAPPLE

Circuit Description

Circuit Diagram

Grapple Connections To Boom

Grapple Control Valves

Grapple Pump

Joystick Control Valve

Pressure Settings

-DELIMBER/SLASHER

Circuit Description

Circuit Diagram

Control Valve Delimber

Control Valve Saws Retract Slasher Cut

Delimber/Slasher Connections

Delimber/Slasher Pump

Flow Adjustment Potentiometers

Fuse And Relay Panel

Pressure Settings

Saw Flow Control Potentiometers

Trouble Shooting Delimber Relay Circuit

-CIRCLE SAW

Circle Saw Circuit Components

Circle Saw Connections

Circle Saw Motor Control Valve

Electrical Diagram – Circle Saw

Lower Frame Hydraulic Connections

Main Hydraulic Circuit

Main Valves

Pilot Circuit-Circle Saw

Pressure Settings

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet