Factory Service Manual For Tigercat Loader. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 686

Number: 45701AENG (january 2016)

Bookmarks

Searchable

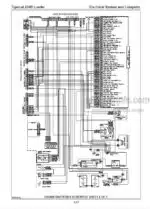

Wiring Diagrams

Hydraulic Diagrams

Model

Tigercat Loader

234B

Serial Number 2342101 To 2344000

Contents

INTRODUCTION

MACHINE IDENTIFICATION AND SERIAL NUMBERS

NON-APPROVED FIELD PRODUCT CHANGES

REGULATORY INFORMATION

-SAFETY

Battery Disconnect Switch

Battery Safety

Before Welding

Cab Exits

Cooling System

DEF (Diesel Exhaust Fluid)

Emergency Cab Exits

Engine Doors

Exhaust Fumes

Fire Prevention

Fluid Injection Injury

Fluid Leaks

Grease Injection Injury

Hydraulic Pressure Hazard

Lightning Safety Awareness

Loose Clothing Hazard

Protective Clothing

Safety Labels

Safety Precautions, General

Safety Precautions, Operating

Safety Precautions, Servicing

Safety Symbols

Signal Words

Welding, Prior To

Working With Oil

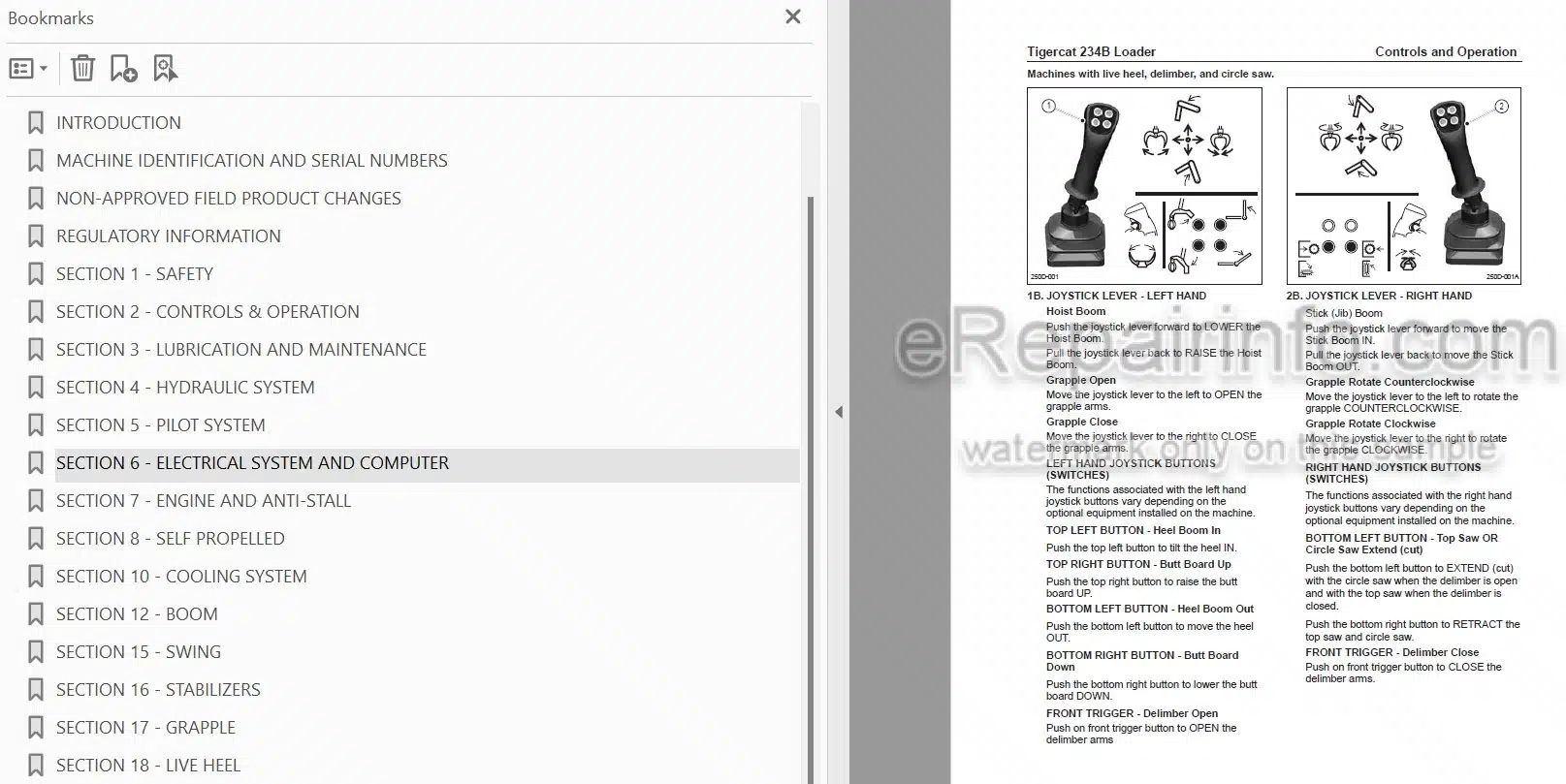

-CONTROLS & OPERATION

A/C On/Off Switch

Air Cleaner

Air Cleaner Unloader Valve

Air Conditioner/Heater

Air Filter Restriction Indicator

Air Intake System

Air Precleaner

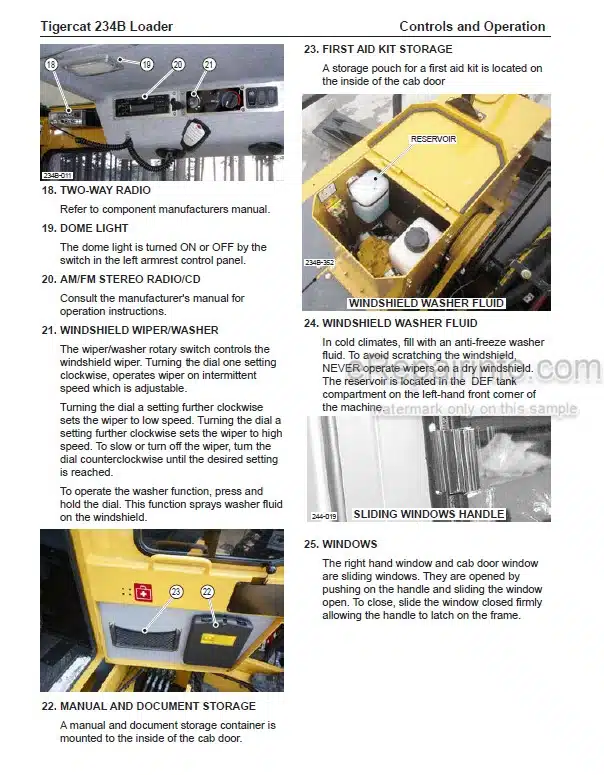

AM/FM Stereo Radio/CD

Auxiliary Power, 12V

Battery Compartment

Battery Disconnect Switch

Cab Controls

Cab Tilting Procedure

Care Of Machine

Case Drain Strainer

Cell Phone Holder

Charge Pressure Filter

Cold Weather Starting

Computer

Control Panel

Cooler Package, Cleaning

Cooling Fan – Switch

DEF (Diesel Exhaust Fluid)

DEFtank

Diesel Exhaust Fluid (DEF) Level Warnings

Diesel Exhaust Fluid (DEF) Tank

Emergency Stop Switch

Engine Compartment

Engine Coolant Heater Controls, Optional

Engine Diagnostics Connection

Engine Fault Code Messages – Critical

Engine, Restarting After Engine Runs Out Of Fuel

Engine Starting

Engine Stopping

Fan – Ventilation

Filter

Fire Extinguisher

Foot Pedal, Swing

Fuel

Fuel Filter / Water Separator

Fuses And Relays

Gauges And Alarms

Hand Fill Pump

Heater Controls, Cab

Heater Controls, Engine Coolant

Horn

Hot Water Shut Off Valve

Hydraulic Oil

Hydraulic Pilot Filter

Hydraulic Return Filters

Icons, Pictogram Descriptions

Interlock Limit Switch

Key Switch

Light-Dome

Lights – Service Light Switch

Lights – Work Light Switch

Loader Mounting/Installation

Machine Operation

Machine Preparation

Md3 Computer

Md3 Computer Main Menu

Panel Control

Pictogram Descriptions

Precleaner, Air

Pre-Start Checks

Pump, Hand Fill, Hydraulic Oil

Radio 2 Way

Refueling

Seat

Setting The Machine

Starting The Engine

Stopping The Engine

Strainer, Case Drain

Tank, DEF

Tank, Hydraulic Oil

Trailer Mounting

USB Port – Md3 Computer

Vacuum Switch, Hydraulic Tank

Wait To Start

Windows

Windshield Washer Fluid

Windshield Wiper/Washer

-LUBRICATION AND MAINTENANCE

Aftertreatment System

Air Cleaner

Air Conditioning

Air Intake System

Air Intake Tubing And Joints

Air Precleaner

Approved Hydraulic Oils

Case Drain Strainer

Cooler Package, Cleaning

DEF (Diesel Exhaust Fluid)

Filters

Fire Prevention

Fuel Filter – Engine

Fuel Filter / Water Separator 2342101 To 2342248

Fuel Filter / Water Separator 2342249 To 2344000

Fuel, Refueling

Fuel Tank And Filler

Hand Fill Pump

Hydraulic Oil

Hydraulic Oil Return Filters

Hydraulic Tank Vacuum System

Lubrication And Service Points

New Machine Maintenance

Oil Lost From Leakage

Oil Sample Collection Procedures

Oil Sampling Program

Pag Oil

Pilot Pressure Filter

Pressure Settings

Preventive Maintenance Schedule

Refrigerant

Refueling

Rotary Manifold Lubrication

Scheduled Maintenance

Service And Lubrication Points

Strainer, Case Drain

Swing Drive Lubrication

Torque Chart, General

Torque, Fluid Connections

Torque Settings, Recommended

Vacuum System, Hydraulic Tank

Weights Of Commercial Wood

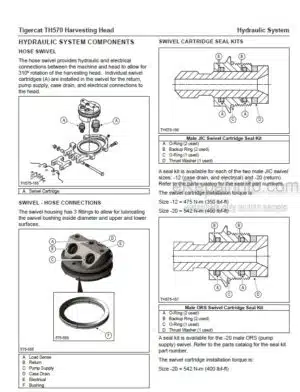

-HYDRAULIC SYSTEM

Circuit Diagram

Electronic Controls Description

Hydraulic Oil Reservoir

Hydraulic Pumps

Hydraulic System Operation

Load Sensing

Main Control Valve

Main Pump Por Valve Setting

Por Valve Setting

-PILOT SYSTEM

Electronic Controls Description

Pilot Electrical Diagrams

Pilot Hydraulic Circuit Diagrams

Pilot Hydraulic Schematic (Electronic Foot Pedals)

Pilot Hydraulic Schematic (Hydraulic Foot Pedals)

Pilot System Components

Pressure Settings

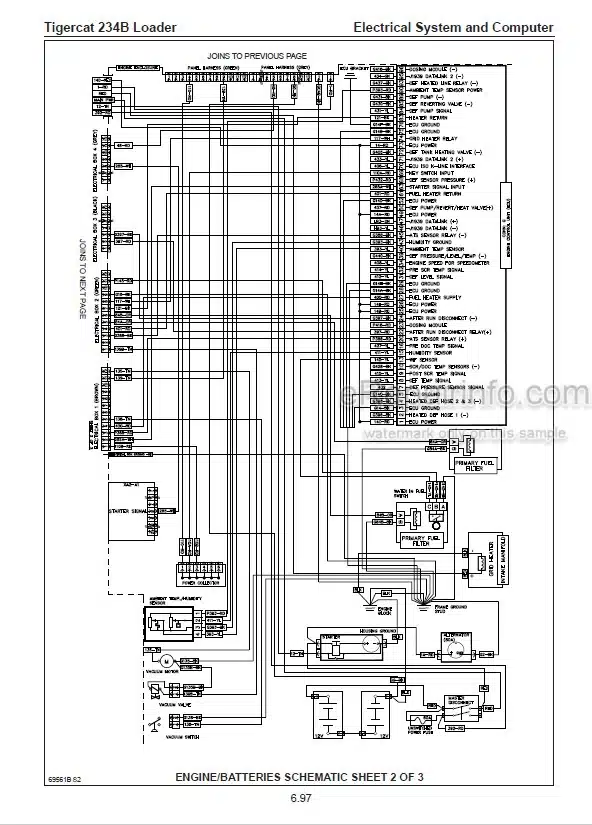

-ELECTRICAL SYSTEM AND COMPUTER

Alternator

Battery Compartment

Battery Disconnect – Switch

Channels

Cold Weather Starting

Computer

Connect To The Md3 With IQANRUN 3

Diesel Exhaust Fluid (DEF) Level Warnings

Downloading Applications From Dealer Website

Electrical Kit – Service And Diagnostics

Electrical Schematics

Electrical System

Engine Fault Code Messages – Critical

Fuses And Relays

Gauges And Alarms

IQANRUN 3

IQAN Software

MD3 Computer

MD3 Computer Main Menu

MD3 Controller Replacement

Relays And Fuses

Sensors And Electrical Component Locations

Servicing The Md3 With IQANRUN 3

Update Application

Wait To Start

-ENGINE AND ANTI-STALL

Anti-Stall

Electrical Schematic – Engine Management

Emergency Stop Circuit

Emergency Stop Switch

Engine Start Circuit

-SELF PROPELLED

Ac16 Circuit Components

Circuit Components (AC16)

Circuit Components (Self Propelled)

Circuit Description (AC16)

Circuit Description (Self Propelled)

Circuit Diagrams

Electronic Adjustment Procedure

Electronic Settings Description

Pressure Settings (AC16)

Pressure Settings, Port Relief Valves

Pressure Settings (Self Propelled)

Schematics

Self Propelled Circuit Components

-COOLING SYSTEM

Charge Air Cooler

Computer

Cooling System

Engine Belts

Oil Cooler

Oil Cooler, Radiator And Fan

Radiator

Variable Pitch Fan (Option)

-BOOM

Adjust Oil Flow To Cylinders (Cylinder Cycle Times)

Boom Circuit Description

Boom System Components

Boom Valve Spool Sections (Electronic Joysticks)

Boom Valve Spool Sections (Hydraulic Joysticks)

Circuit Diagrams

Cylinder Cycle Times, Typical

Electronic Adjustment Procedure

Electronic Settings Description

Hoist Valve Relief Valve Settings

Operator Mode

Pilot Electrical Diagrams

Pressure Settings

Pressure Settings, Port Relief Valves

Stick Valve Relief Valve Settings

-SWING

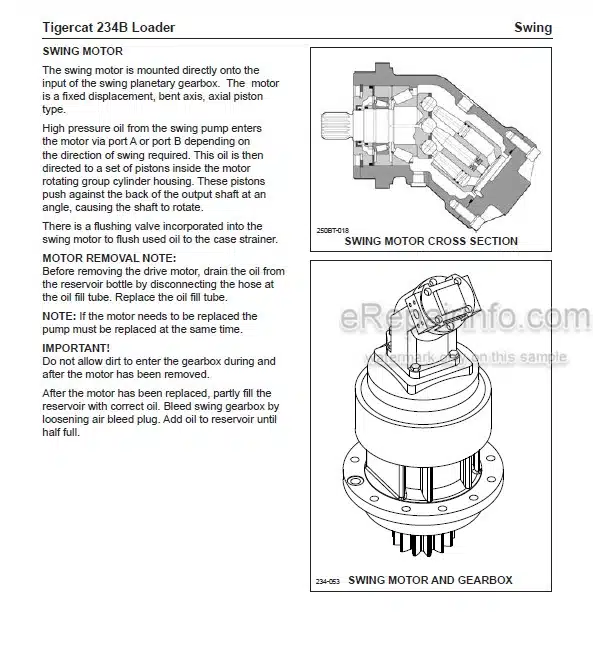

Circuit Description

Circuit Diagrams

Electronic Adjustment Procedure

Electronic Settings Description

Gearbox, Swing Drive

Hydrostatic Drive Motor

Lens Plate Timing Adjustment

Operator Mode

Pressure Settings

Pressure Settings, Port Relief Valves

Swing Bearing

Swing Brake (Self Propelled/Ac 16)

Swing Motor

Swing Pump

-STABILIZERS

Circuit Components

Control Valve

Counterbalance And Check Cartridges, Removal

Counterbalance Valves

Cylinders And Counterbalance Valves

Lowering Stabilizer

Pressure Settings

Raising Stabilizer

Stabilizer Circuit Description

Stabilizer Electrical Circuit Schematic

Stabilizer Hydraulic Circuit Schematic

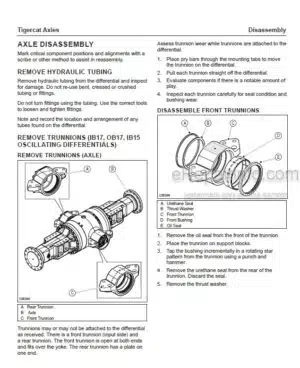

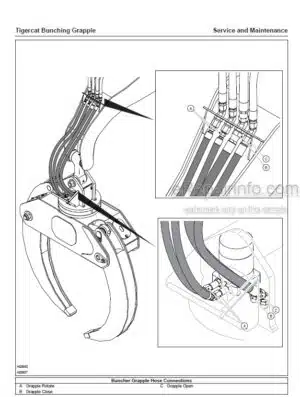

-GRAPPLE

Adjust Oil Flow To Cylinders (Cylinder Cycle Times)

Circuit Description (Electronic Joysticks)

Circuit Description (Hydraulic Joysticks)

Circuit Diagrams

Cylinder Cycle Times, Typical

Electronic Adjustment Procedure

Electronic Settings Description

Grapple Connections To Boom

Grapple System Components

Operator Mode

Pressure Settings

Pressure Settings, Port Relief Valves

-LIVE HEEL

Circuit Diagrams

Cylinder Cycle Times, Typical

Electronic Adjustment Procedure

Electronic Settings Description

Live Heel Circuit Description

Live Heel Components

Live Heel Relief Valve Settings

Operator Mode

Pressure Settings

-DELIMBER/SLASHER AND CIRCLE SAW

Circle Saw Circuit Components

Circuit Description (Circle Saw)

Circuit Description (Delimber/Slasher)

Circuit Diagrams

Computer

Control Valve Delimber

Control Valve Saw Retract Slasher Cut

Delimber/Slasher Circuit Components

Delimber/Slasher Connections

Delimber/Slasher Electrical

Delimber/Slasher Pump

Electronic Adjustment Procedure (Circle Saw)

Pressure Settings For Circle Saw Cut And Retract

Pressure Settings For Top Saw Cut, Slasher Cut And Delimber

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet