Factory Service Manual For Tigercat Mulcher. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Quantity of Manuals: 2

Pages: 474; 530

Number: 55991AENG (november 2020; february 2021)

Bookmarks

Searchable

Wiring Diagrams

Hydraulic Diagrams

Model

Tigercat Mulcher

470

Serial Number 4702001–4702500

Contents

-INTRODUCTION

Machine Identification And Serial Numbers

Standards For Machine Operator Protective Structures

Non-Approved Field Product Changes

Regulatory Information

Warranty-EPA

-SAFETY

Avoid Injury From Backover Accidents

Battery Disconnect Switch

Battery Safety

Boom Cylinder Lock

Cab Exits

Cab Tilt Support Link

Cooling System

Diesel Exhaust Fluid (DEF)

Exhaust Fumes

Fire Prevention

Fluid Injection Injury

General Safety Precautions

Grease Injection Injury

Hazard Zone

Interlock Door And Armrest Switches

Lightning Safety Awareness

Loose Clothing Hazard

Machine Stability And Traction

Mulching Operation Safety

Notice Labels

Operating Safety Precautions

Parking The Machine

Pilot System Pressure Release

Pneumatic Grease Guns, Using

Protective Clothing

Release Pilot System Pressure

Safety Hazards

Safety Labels

Safety Precautions

Safety Signal Words

Safety Symbols

Servicing Safety Precautions

Transporting The Machine

Welding, Prior To

Working With Oil

-CONTROLS AND OPERATION

Air Compressor–Air Supply

Air Conditioning Controls

Air Vents, Cab

Alarm

Alarm Light

Attachment Switch

Attachment Tilt

Audio System

Auxiliary Power Supply, 12 V

Batteries

Battery Boosting

Battery Disconnect Switch

Boom Float

Boom Lift

Cab Features

Cameras And Monitor

Cold Weather Starting

Computer

Computer And Display

Control Panels

Cruise Control

Debris Door Open/Close

Emergency Engine Stop Button

Emergency Exit

Engine

Engine Coolant Heater Control (Optional)

Ethernet Connection

Fan Switch (Engine Cooling)

Filters

Fire Detection System

Fire Extinguisher

Fire Suppression System (Optional)

Heater, Engine Coolant (Optional)

Horn

Interlock Reset Switch

Joystick Controls

Lighter, 24 V

Lights

Machine Preparation

Master Alarm

Mirrors, Rearview

Operating Machine

Operator’s Manual Case

Pictograms

Radios

Rear View Mirrors

Refuelling

Seat, Operator’s

Service Lights

Slope Indicators

Starting Engine

Steering

Stopping Engine

Switches

Telematics System

Track Operation And Wear Prevention

Travelling

USB Ports

Winch

Windshield Washer Fluid Bottle

Work Lights

-LUBRICATION AND MAINTENANCE

Access Doors And Covers

Aftertreatment System

Aftertreatment System (Tier 4F Machines Only)

Air Conditioning System

Air Intake System

Anti-Corrosion Spray, Removal

Approved Hydraulic Oils

Battery Care

Belt, Serpentine

Cab Tilt

Care Of Polycarbonate Windows

Care Of The Machine

Cleaning Cooler Package

Commercial Wood, Weights

Debris Screen

Diesel Exhaust Fluid (DEF) (Tier 4F Machines Only)

Diesel Exhaust Fluid Tank

Emergency Exits

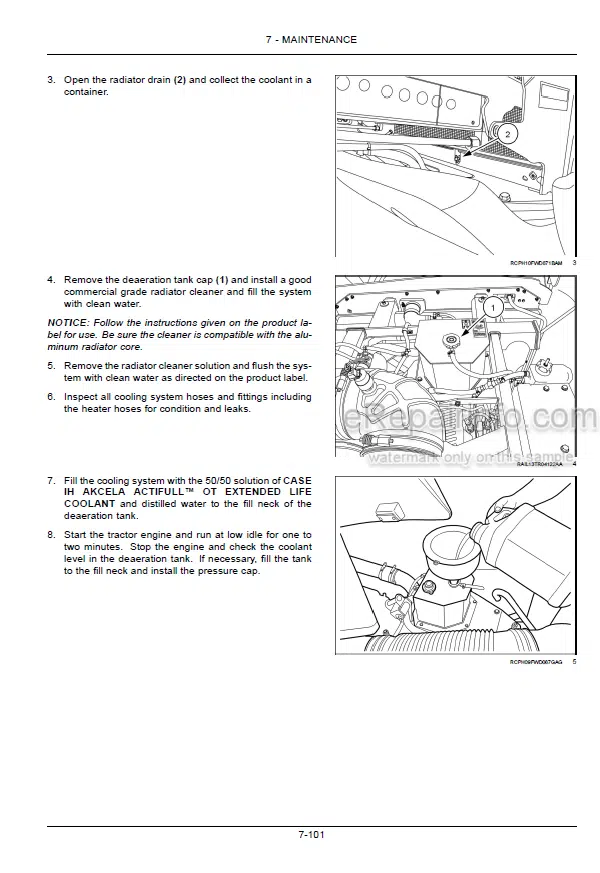

Engine Coolant

Engine Coolant Heater Unit (Optional)

Filters

Fire Prevention

Fluid Analysis Program

Fluid Sampling Program

Fuel, Refuelling Procedure

Fuel Tank

Fuses And Relays

Graffiti Removal

Hydraulic Oil Operating Range Chart

Hydraulic System

New Machine Maintenance

Pressure And Speed Settings

Pressure Washing

Preventive Maintenance Schedule

Pump Drive Gearbox

Refilling The Hydraulic System

Refuelling Procedure

Remote Fuel Tank Filling

Scheduled Maintenance

Serpentine Belt

Service And Lubrication Points

Start-Up Procedure After Maintenance

Strainers

Torque Chart, Fluid Connections

Torque Chart, General

Torque Chart, Specific

Track Drive Gearbox

Tracks

Winch

Windows

Window Screens

-HYDRAULIC SYSTEM

Attachment Control Valve

Electrical Schematic -XA2-A0 Module

Electrical Schematic-XA2-A1 Module

Gauge Fittings

Hydraulic System Circuits

Main Hydraulic System

Main Pump

Main Pump And Main Valve Operation

Main Valve

Pressure Settings

-PILOT SYSTEM

Circuit Components

Circuit Schematic

General Description

Interlock System

Main Valve

Pressure Settings

-ELECTRICAL AND COMPUTERS

Aftertreatment System Sensors And Electrical Components

Battery Disconnect Switch

Cab Electrical Components

Channels

Chassis Sensors And Electrical Components

Communication Cable

Computer Control System

Electrical Kit-Service And Diagnostics

Electrical Schematic

Electrical System

Engine Diagnostics Connection

Engine Electrical Cables

Fuses And Relays

ID-Tags

IQAN Program Software

Machine Program Updates

Telematics System

XA2 Modules

-ENGINE

Engine

Pump Drive Gearbox

Start Circuit

-COOLING SYSTEM

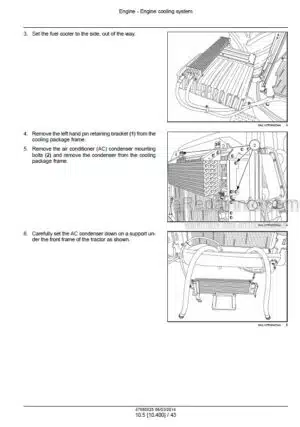

A/C Condenser

Aftertreatment System Cooling

Charge Air Cooler (CAC)

Cooler Package

Cooling Fan

Engine Coolant Heater Unit (Optional)

Hydraulic Oil Cooler

Pressure Settings

Pump Drive Gearbox Cooler

Radiator

-TRACK DRIVE

Circuit Components

Circuit Schematic

Drive Motors

Drive Pumps

Hydrostatic Drive System

Important Track Drive Notes

Measuring Track Sag

Setup Procedure

Torquing Undercarriage Bolts

Track Brakes Hydraulic Schematic

Track Drive Undercarriage

Track Sag

Track Speed Setup Procedure

Wear Limits

-LIFT BOOM

Circuit Components

Circuit Description

Circuit Schematic

Joystick-Right

Main Valve

Pressure Settings

Safety Precautions

-TILT BOOM

Circuit Components

Circuit Description

Circuit Schematic

Joystick-Right

Main Valve

Pressure Settings

Safety Precautions

-ATTACHMENT DRIVE

Attachment Control Valve

Attachment Motors

Attachment Pump

Attachment Pump And Attachment Control Valve Operation

Circuit Components

Circuit Description

Circuit Schematic

Pressure And Speed Settings

Safety Precautions

-PUSH BAR AND DEBRIS DOOR

Attachment Components

Circuit Components

Circuit Descriptions

Circuit Schematic

Main Valve

Pressure Settings

Safety Precautions

-WINCH

Circuit Components

Circuit Description

Circuit Schematic

Main Valve

Pressure Settings

Safety Precautions

Winch

-COMPRESSED AIR SYSTEM

Components

Overview

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

![Product Tigercat 470 Service Manual Mulcher 55991AENG SN3 [2] Photo 1 - Tigercat 470 Service Manual Mulcher 55991AENG SN3 [2]](https://erepair-info.com/wp-content/uploads/2023/07/1/07/Tigercat_470_Service_Manual_Mulcher_2023-05-08_12-15-00.jpg.webp)

![Product Buy and download Tigercat 470 Service Manual Mulcher 55991AENG SN3 [2] manuals in PDF Products photo Buy and download Tigercat 470 Service Manual Mulcher 55991AENG SN3 [2] manuals in PDF](https://erepair-info.com/wp-content/uploads/2023/07/1/07/Tigercat_470_Service_Manual_Mulcher_2023-05-08_12-14-31.jpg.webp)

![Product Buy and download Tigercat 470 Service Manual Mulcher 55991AENG SN3 [2] manuals in PDF Products photo Buy and download Tigercat 470 Service Manual Mulcher 55991AENG SN3 [2] manuals in PDF](https://erepair-info.com/wp-content/uploads/2023/07/1/07/Tigercat_470_Service_Manual_Mulcher_2023-05-08_12-14-07.jpg.webp)

![Product Buy and download Tigercat 470 Service Manual Mulcher 55991AENG SN3 [2] manuals in PDF Products photo Buy and download Tigercat 470 Service Manual Mulcher 55991AENG SN3 [2] manuals in PDF](https://erepair-info.com/wp-content/uploads/2023/07/1/07/Tigercat_470_Service_Manual_Mulcher_2023-05-08_12-15-32.jpg.webp)

![Product Tigercat 470 Service Manual Mulcher 55991AENG SN3 [2] Photo 2 - Tigercat 470 Service Manual Mulcher 55991AENG SN3 [2]](https://erepair-info.com/wp-content/uploads/2023/07/1/07/Tigercat_470_Service_Manual_Mulcher_2023-05-08_12-15-00-150x172.jpg.webp)

![Product Tigercat 470 Service Manual Mulcher 55991AENG SN3 [2] Photo 3 - Tigercat 470 Service Manual Mulcher 55991AENG SN3 [2]](https://erepair-info.com/wp-content/uploads/2023/07/1/07/Tigercat_470_Service_Manual_Mulcher_2023-05-08_12-14-31-150x76.jpg.webp)

![Product Tigercat 470 Service Manual Mulcher 55991AENG SN3 [2] Photo 4 - Tigercat 470 Service Manual Mulcher 55991AENG SN3 [2]](https://erepair-info.com/wp-content/uploads/2023/07/1/07/Tigercat_470_Service_Manual_Mulcher_2023-05-08_12-14-07-150x92.jpg.webp)

![Product Tigercat 470 Service Manual Mulcher 55991AENG SN3 [2] Photo 5 - Tigercat 470 Service Manual Mulcher 55991AENG SN3 [2]](https://erepair-info.com/wp-content/uploads/2023/07/1/07/Tigercat_470_Service_Manual_Mulcher_2023-05-08_12-15-32-150x204.jpg.webp)

![Photo 6 - Tigercat 470 Service Manual Mulcher 55991AENG SN3 [2]](https://erepair-info.com/wp-content/uploads/2023/07/1/07/Tigercat_470_Service_Manual_Mulcher_2023-05-08_11-48-14-300x398.jpg.webp)

![Photo 7 - Tigercat 470 Service Manual Mulcher 55991AENG SN3 [2]](https://erepair-info.com/wp-content/uploads/2023/07/1/07/Tigercat_480_Service_Manual_Mulcher_2023-05-08_14-15-25-300x409.jpg.webp)

Reviews

There are no reviews yet