Factory Service Manual For Tigercat Skidder. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 598

Number: 41336AENG (july 2017)

Bookmarks

Searchable

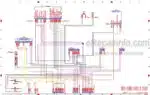

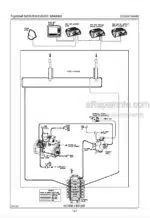

Wiring Diagrams

Hydraulic Diagrams

Model

Tigercat Skidder

620E

630E

635E

Serial Number 6206201 To 6206400

Serial Number 6304001 To 6304200

Serial Number 6351501 To 6352000

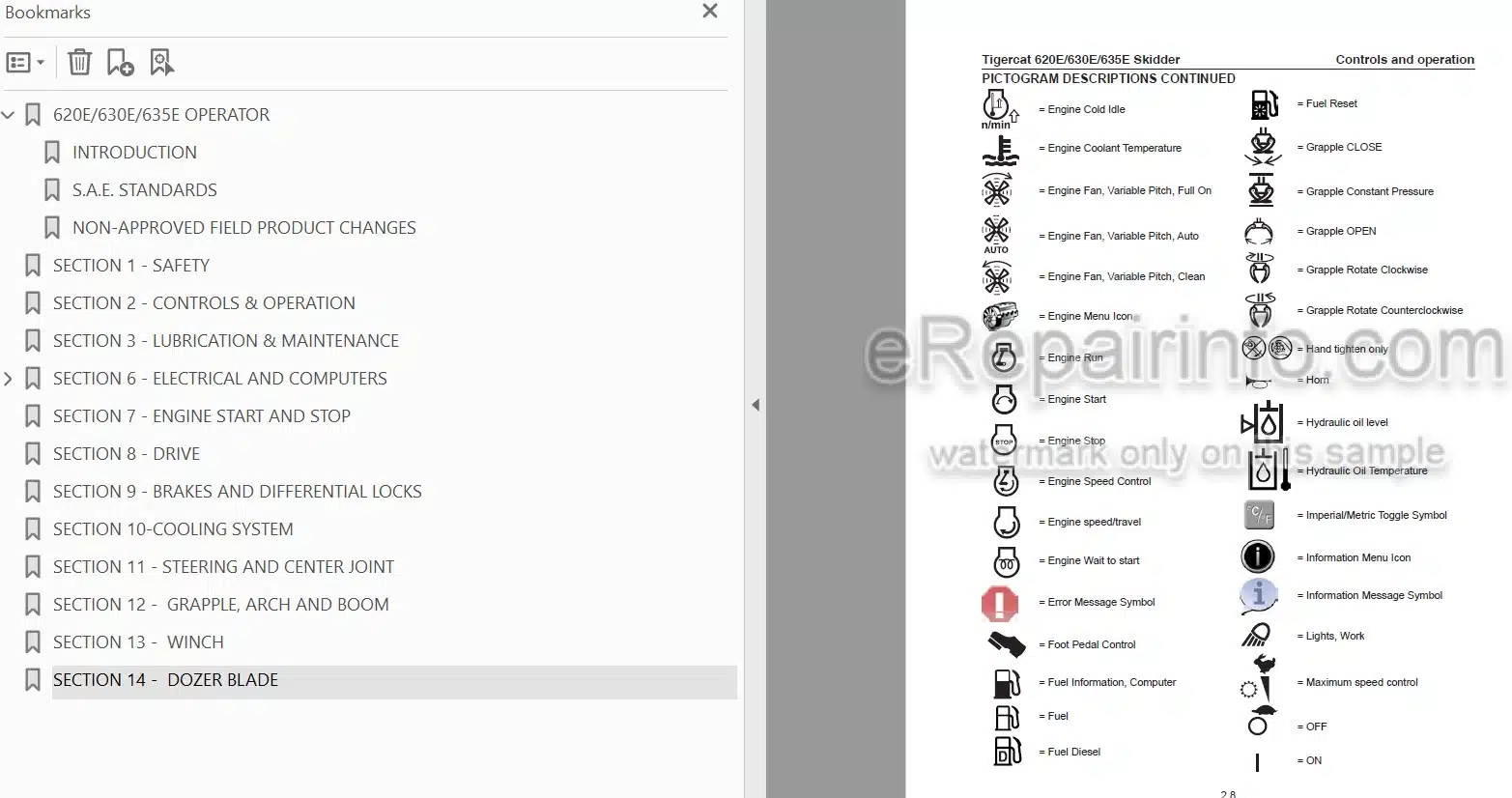

Contents

INTRODUCTION

SAE STANDARDS

NON-APPROVED FIELD PRODUCT CHANGES

-SAFETY

Articulation Lock

Battery Disconnect Switch

Battery Safety

Cab Exits

Cab Safety Cable

Cab Support Brace

Cooling System

Diesel Exhaust Fluid (DEF)

Emergency Cab Exits

Exhaust Fumes

Fire Prevention

First Aid

Fluid Injection Injury

Fluid Leaks

Grease Injection Injury

Hydraulic Pressure Hazard

Lightning Safety Awareness

Loose Clothing Hazard

Noise Level Inside Cab

Parking The Machine

Protective Clothing

Safety Labels

Safety Precautions, General

Safety Precautions, Operating

Safety Precautions, Servicing

Safety Symbols

Signal Words

Vibration Levels Inside Cab

Welding, Prior To

Working With Oil

-CONTROLS & OPERATION

Access Panels And Doors

Articulation Lock

Battery Disconnect Switch

Cab Controls

Cab Ventilation

Care Of The Machine

Denox Fault Code Messages – Alert

Denox Fault Code Messages – Critical

Diesel Exhaust Fluid (DEF) Level Warnings

Diesel Exhaust Fluid (DEF) Quality Warning

Diesel Exhaust Fluid (DEF) Tank

Doors And Access Panels

Engine Air Cleaner

Engine Fault Code Messages – Alert

Engine Fault Code Messages – Critical

Fire Extinguisher, Portable

Fire Prevention

Fuel Tank

Fuse And Relay Panels

Grapple, Operating

Hydraulic Fill Pump

Hydraulic Filters

Hydraulic Oil Tank

Moving Instructions

Operating Machine

Parking Brake Switch

Pictogram Descriptions

Pre Start Checks

Radio, AM/FM CD

Radio, CB (If Equipped)

Retrieval Points

Rotating Seat Kick Lever

Skidding

Starting Engine

Steering

Stereo AM/FM CD

Stopping Engine

System Test And Warm-Up

System Warning Messages

Tilt Cab

Towing Instructions

Towing Instructions – EHS Transmission

Transmission Dipstick

Transmission Oil Fill Location

Transporting Instructions

Winch, Operating

-LUBRICATION & MAINTENANCE

After Treatment System

Air Cleaner Maintenance

Air Conditioning System, Checking

Approved Anti-Seize Pastes For Exhaust / After Treatment Line

Approved Hydraulic Oils

Articulation Lock

Axle

Cab Safety Cable

Cab Support Brace

Center Joint

Denox 2 System

Depressurizing Suspended Machine Elements

Diesel Exhaust Fluid (DEF) Handling

Draining Engine Coolant

Draining Hydraulic Tank

Draining The Diesel Exhaust Fluid Tank

Draining The Fuel Tank

Draining Transmission Oil

Emergency Exits, Check Monthly

Filling Hydraulic Tank

Filters

Fire Prevention

Fluid Analysis Program

Fuel, Refuelling Procedure

General Maintenance

Grapple Snubber Maintenance

Hour Meter ~ Maintenance

Lubrication And Service Points

New Machine Maintenance

Oil Lost From Leakage

Parking Brake

Pressurized Water System Maintenance

Refuelling Procedure

Scheduled Maintenance

Selective Catalytic Reduction After Treatment System (Denox 2 System)

Service And Lubrication Points

Service Brake

Start-Up Procedure After Major Maintenance

Tilting The Cab

Tire Pressures

Torque Chart, General

Torque, Fluid Connections

Weights Of Commercial Wood

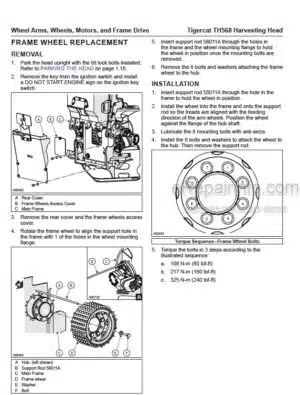

Wheels, Installing

Winch Maintenance – Allied Winch

Winch Maintenance – Carco

-ELECTRICAL AND COMPUTERS

Alarms And Gauges

Channels

Computer

Connect To The Md3 With IQANRUN 2

Diagnostic Breakout Harnesses

Downloading Applications From Dealer Website

Electrical Kit – Service And Diagnostics

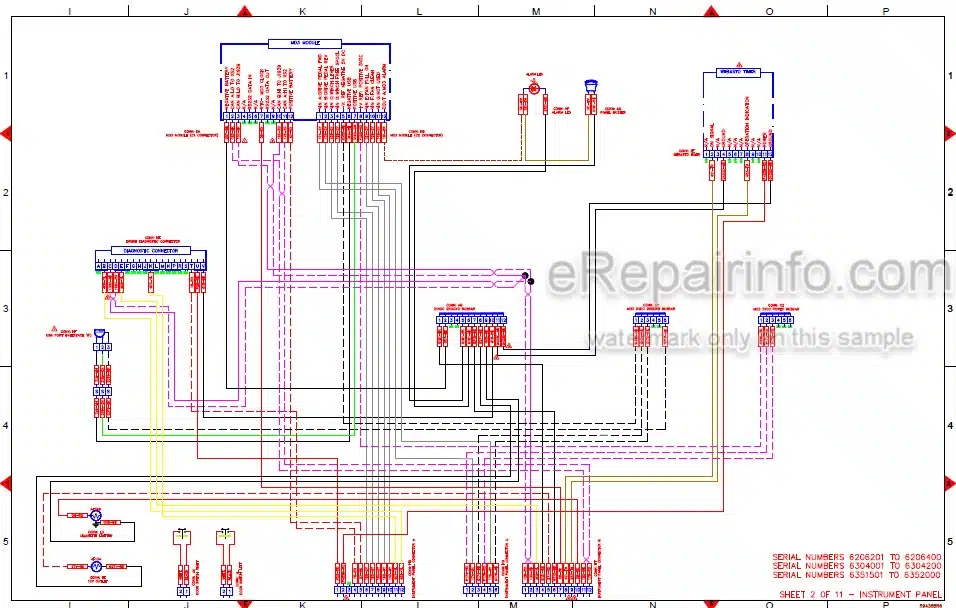

Electrical System Schematic Diagrams

Fuse And Relay Panels

Gauges And Alarms

ID-Tag

Input And Output Channels

IQAN Modules

IQANRUN 2

IQAN Software

Servicing The Md3 With IQANRUN 2

Switch And Sensor Locations

Troubleshooting Diagnostic Breakout Harnesses

Update Application

Wire Colour Code Chart

-ENGINE START AND STOP

Engine Flex Drive Coupler Installation

Main Pump Unloading Valve

Start Circuit Diagrams

Starting Engine

Starting In Cold Weather

Start Motor And Solenoid

Stopping Engine

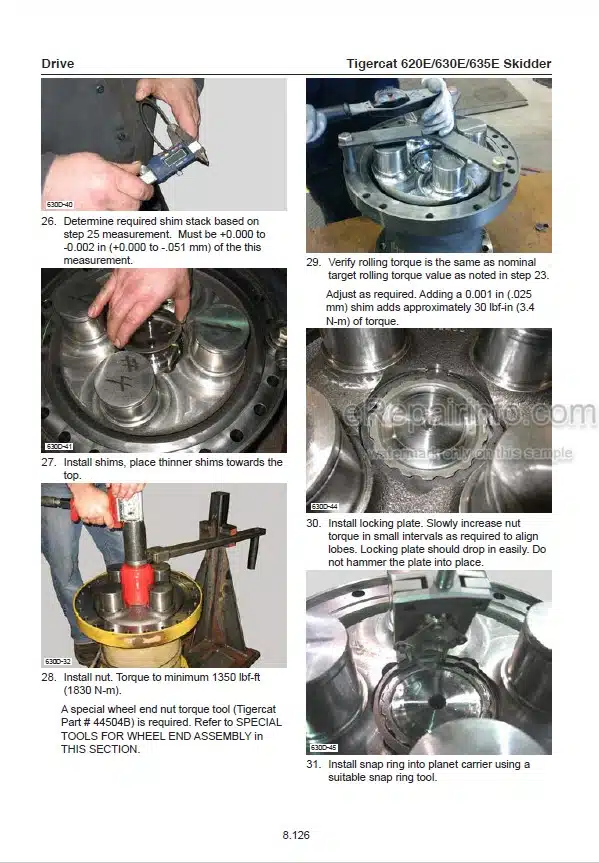

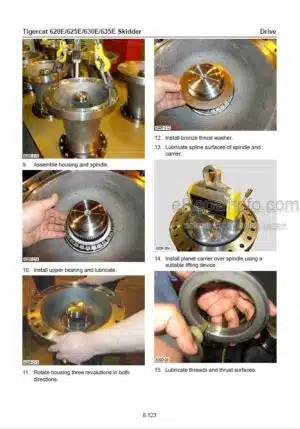

-DRIVE

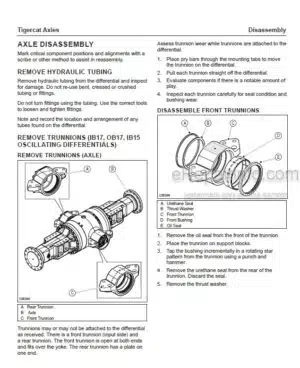

Axle

Charge Pump (Drive)

Circuit Description

Circuit Diagram

Circuit Hydraulic Schematic

Direction Selection Switch Rotating Seat & Joystick Steering

Drive Motor

Drive Motor Speed Verification

Drive Pump

Drive Pump Pressure Checks

EHS Transmission Cooler

Hydraulic Oil Heating Procedure

Hydrostatic Drive System

Hydrostatic Setup Procedure

Hydrostatic Setup Sheet

Maximum Speed Control

Special Tools For Wheel End Assembly

Startup Procedure After Major Maintenance

Transmission

Transmission Pump

Travel/Engine Speed Pedals

Wheel Installation

-BRAKES AND DIFFERENTIAL LOCKS

Accumulator

Charging Valve, Accumulator

Circuit Description

Circuit Diagram

Circuit Hydraulic Schematic

Main Pump

Main Pump Unloading Valve

Multifunction Manifold

Parking Brake

Pressure Settings Main Pump Por And Standby Pressures

Priority Valve

Service Brakes

-COOLING SYSTEM

Cooler Package

Cooler Package Components

Cooling Pump

EHS Transmission Cooler

Hydraulic Oil Tank

Multifunction Manifold

Multifunction Manifold

Oil Cooler

Suction Strainer

Variable Pitch Fan (Optional)

-STEERING AND CENTER JOINT

Centre Joint

Joystick Steering & Rotating Seat

Priority Valve

Steering Wheel & Stationary Seat

-GRAPPLE, ARCH AND BOOM

Circuit Description

Circuit Diagrams

Control Valve

Control Valve Electrical Schematic

Grapple Rotate Speed Check

Grapple Rotator Assembly

Grapple Snubber Maintenance

Hydraulic Schematic, Circuit

IQAN Modules

Joystick (6-Button)

Main Pump

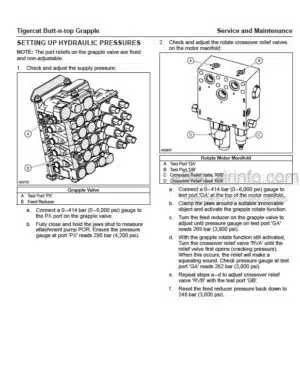

Pressure Checks And Adjustments

Priority Valve

Snubber Maintenance – Grapple

-WINCH

Allied Winch

Carco Winch

Control Valve

Multifunction Manifold

Pressure Checks

Pressure Settings Secondary Por, Main Pump Por And Standby Pressures (High Speed Winch Only)

Secondary Por (High Speed Winch Only)

Winch Maintenance – Allied

Winch Maintenance – Carco

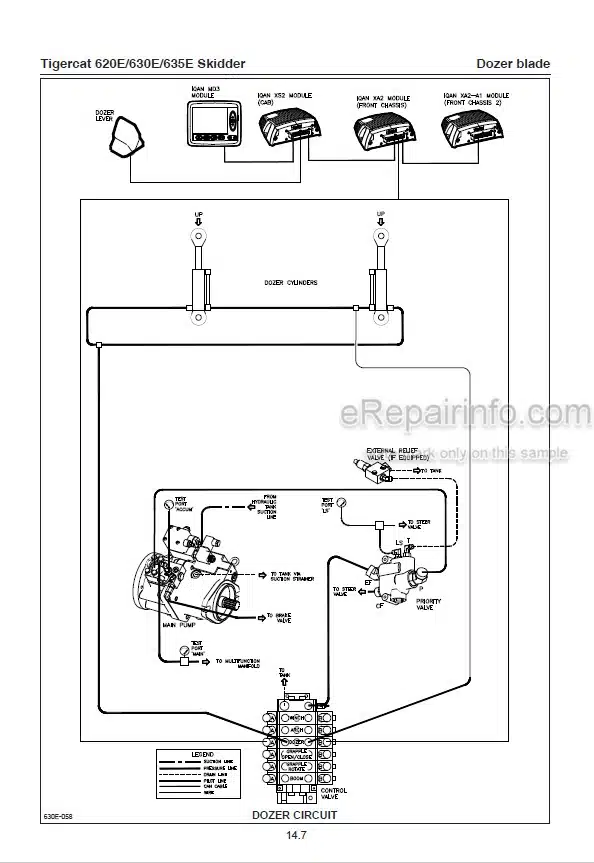

-DOZER BLADE

Circuit Description

Circuit Diagram

Circuit Hydraulic Schematic

Control Valve

Dozer Blade Control Lever

Pressure Checks

Secondary Por

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet