Factory Service And Maintenance Manual For Tigercat Feller Buncher. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 256

Number: 30851A (july 2015)

Bookmarks

Searchable

Wiring Diagrams

Hydraulic Diagrams

Model

Tigercat Feller Buncher

718E

Serial Number 7180901 To 7182000

Contents

INTRODUCTION

NON-APPROVED FIELD PRODUCT CHANGES

-SAFETY

Access Panels

Backover Accidents

Battery Safety

Boom Lift Lock

Felling Trees

Fire Prevention

Fluid Injection Injury

Grease Injection Injury

Lightning Safety Awareness

Parking The Machine

Safety Hazards – Operating

Safety Hazards – Viton Seals

Safety Interlock Switches On Cab Doors

Safety Labels

Safety Precautions, General

Safety Precautions, Operating

Safety Precautions, Servicing

Safety Symbols

Signal Words

Working With Oil

-LUBRICATION AND MAINTENANCE

Scheduled Maintenance

Air Cleaner Maintenance

Air Conditioning System Checking

Belt, Engine Serpentine, Replacing

Blink Codes

Center Joint

Drive Shaft Spline Lubrication, Middle And Rear

Filters

Fire Prevention

Hydraulic Oils

New Machine Maintenance

Oil Lost From Leakage

Oil Sample Collection Procedures

Oil Sampling Program

Pressure Settings – Saw

Pressure Settings – Shear

Pressurized Water System Maintenance

Priming The Fuel System

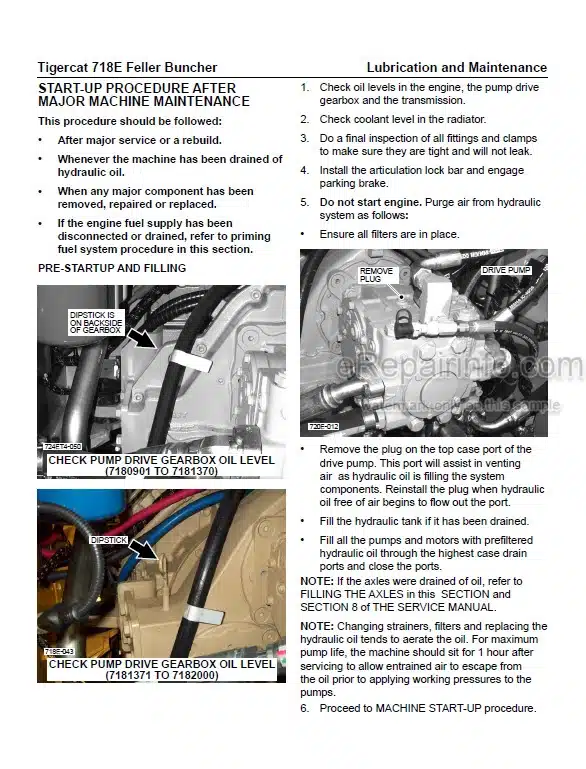

Pump Drive Gearbox Oil Level

Service And Lubrication Points Chart

Speed Control Lever Adjustment

Startup Procedure After Maintenance

Torque Chart, General

Torque, Fluid Connections

Transmission – Check Oil Level

Weights Of Commercial Wood

Wheels, Installing

-PILOT SYSTEM

Accumulator

Accumulator Charge Valve

Accumulators

Components

Hydraulic Oil Heating Procedure

Main Relief Valve Pressure Setting

Pilot Circuit Description

Pilot Circuit Schematic

Pilot Manifold

Pilot Pressure Settings

Pilot System Components

Release Pilot System Pressure

Troubleshooting Guide

Unloading Valve Pressure Setting

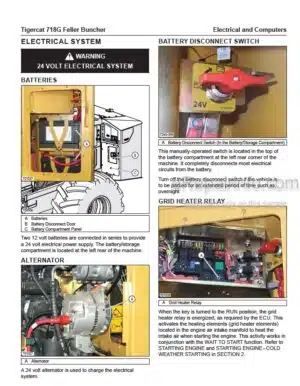

-ELECTRICAL, GAUGES AND ALARMS

Blink Codes

Blink Code Translation / Diagnostics

Electrical Schematics

Fuse And Relay Panel – Cab

Fuse And Relay Panel – Main

Relays And Wire Connections

Sensor, Sender Locations

Wire Color Code Chart

Wire Connections – Relays

-ENGINE

Charge Air Cooler

Circuit Description

Cooling System

Precleaner

Start Circuit Diagrams

Starting System Description

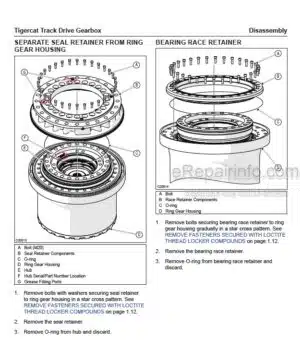

-DRIVE

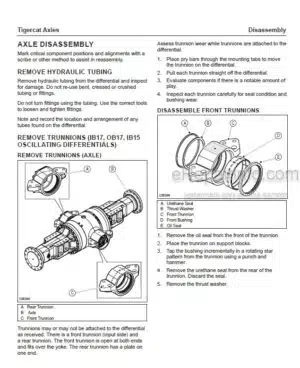

Axles

Circuit Description

Circuit Diagram, Drive

Drive Motor Pressure Settings And Adjustments

Drive Pedal Pilot Valve

Drive Prevent Valve

Drive Pump Pressure Settings And Adjustments

Drive Shaft, Front, Installation

Hydrostatic Drive Motor Description

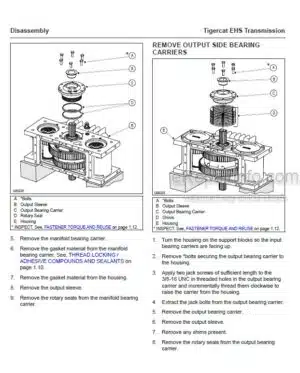

Hydrostatic Drive System-Single Motor 2-Speed Transmission

Parking Brake Operation

Pressure Setting Chart

Pressure Settings And Adjustments

Test Drive

Transmission 2-Speed (Single Motor)

Wheel Installation

-BRAKES AND DIFFERENTIAL LOCKS

Brakes

Differential Locks

Parking Brake – Hydraulic

-COOLING SYSTEM

Charge Air Cooler

Cleaning

Flexxaire Fan Maintenance (Optional Item)

Oil Cooler

Oil Cooler Operation

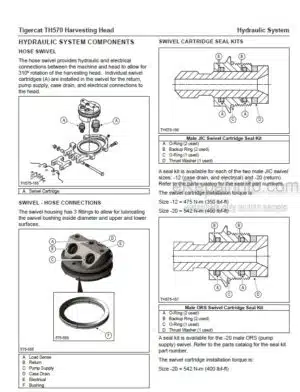

-STEERING AND CENTRE JOINT

Center Joint

Joystick Control Valve

Pilot Manifold

Pressure Setting Chart See Section 3 – Lubrication And Maintenance

Pressure Settings

Safety

Steer/Boom Pump

Steer Circuit

Steer Valve

-LIFT BOOM

Boom Lift Lock

Boom Valve

Circuit Diagram

Joystick Control Valve

Pressure Setting Chart

Pressure Settings

Pump, Description

Relief Valves

-TILT

Boom Lift Lock

Boom Valve

Circuit Description

Circuit Diagram

Control Valves

Pressure Setting Chart

Pressure Settings

Safety

-SAW DRIVE

Circuit Diagram

Motor Begin Of Stroke See Felling Head Manual

Motor Minimum Displacement See Felling Head Manual

Pressure Setting Chart See Section 3 – Lubrication And Maintenance

Saw Control Valve

Saw Electrical Circuit Schematic

Saw Pump

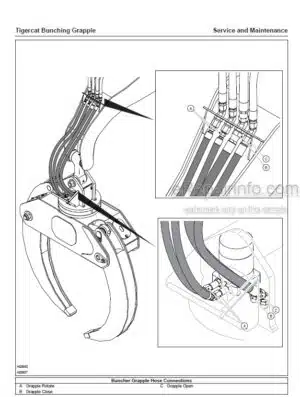

-CLAMPS WITH SAW

Boom Lift Lock

Boom Valve

Circuit Description

Circuit Diagram

Control Valves

Pilot Line Pressures

Pressure Settings

Relief Valves

Safety

Spool Section Diagram

-SHEAR WITH CLAMPS

Boom Lift Lock

Boom Valve

Circuit Description

Circuit Diagram

Control Valves

Foot Operated Pilot Valve

Pressure Settings

Safety

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet