Factory Service Manual For Tigercat Feller Buncher. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 168

Number: 4639A (march 2003)

Bookmarks

Searchable

Wiring Diagrams

Hydraulic Diagrams

Model

Tigercat Feller Buncher

853E

Contents

GENERAL SPECIFICATIONS

-SAFETY

Battery Disconnect Switch

Cooling System

Engine Doors

Exhaust Fumes

Fire Prevention

First Aid

Fluid Leaks

Hydraulic Pressure Hazard

Loose Clothing Hazard

Parking Hazards

Protective Clothing

Safety Precautions, Operating

Safety Precautions, Servicing

Safety Symbols

Signal Words

-USING HIGH SPEED DISC SAWS SAFELY

Comments And Instructions

Dangers

Forward

High Angle Wrist Rotation Capability

Saw Head Don’ts

Type Of Housing Makes A Difference

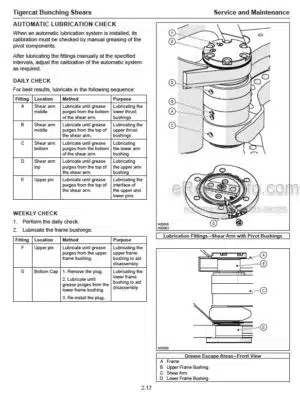

-LUBRICATION & MAINTENANCE

Filter And Lubrication Schedule

First 100 Hours

First 25 Hours

General Maintenance

Hydraulic Oils

Lubricating Cylinder Pins And Boom Joints

Lubrication Schedule

New Machine Maintenance

Pressure Setting Procedures. See Service Manual

Pressure Setting Values. See Service Manual, Section 4

Preventive Maintenance Schedule

Scheduled Maintenance

Tightening Points

Torque Chart, General

Torque Settings, Recommended

Track Tension

-HYDRAULIC SYSTEM

Circuit Schematic

Engine Doors Schematic

High Pressure Limiting Control Valve

Hydraulic Oil Reservoir

Hydraulic Pumps

Hydraulic System Operation

Load Sensing

Main Control Valve

Main Pump Control Valve

Operating Tips

Pressure Settings

Schematic Diagrams

-PILOT SYSTEM

Accumulator

Circuit Schematic

Control Valve Arrangement

Foot Pedal

Joystick Handle Control Valve

Pilot Circuit Description

Pilot Filter

Pilot Supply Manifold

Pilot Supply Valve

Set Flow Control

Set Pilot Flow Control

Set Pilot Pressure

-ELECTRICAL, GAUGES AND ALARMS

Gauges And Alarms

Schematic Diagrams

Sensor Details

Switch And Sensor Locations

Wire Color Code Chart

-ENGINE START AND STOP

Electrical Circuit Description

Engine Starting Circuit

Operating Condition Circuit

Pilot Resume Circuit

Saw Switch ‘on’ At Start Up Circuit

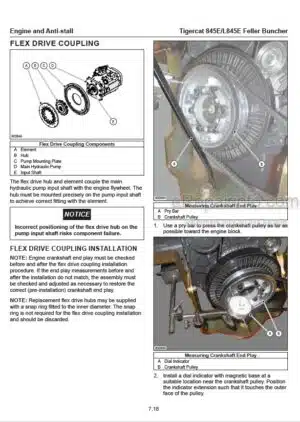

-ENGINE ANTI-STALL

Circuit Schematic

Control Module In Cab

Engine Anti-Stall Curve

Faultfinding

Fault Finding Procedures, Additional

Horsepower Limiting Control

Load Sense; Set Margin Pressure. See Section 4

Set Pilot Pressure. See Section 5

Solenoid Valve

Speed Sensor On Front Of Engine

Verify Anti-Stall Setting. See Section 4

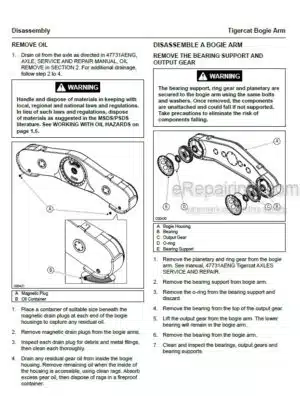

-TRACK DRIVE

Brake Description

Circuit Schematic

Main Control Valve

Pressure Settings

Set Motor Minimum Displacement

Track Components

Track Hydraulics

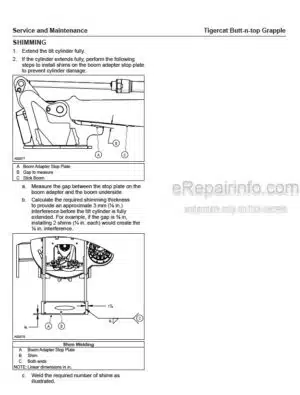

-BOOM FUNCTIONS

Adjust Oil Flow To Cylinders(Cylinder Cycle Times)

Boom Control Valve

Boom System Description

Circuit Schematic

Cylinder Cycle Times, Typical

Engine Anti-Stall

Load Sensing

Set Port Relief Valves

Tilt Cylinder Flow Adjustment

-SWING

Adjust Oil Flow To Swing Motor (Swing Speed)

Circuit Schematic

Disassembly And Assembly Of Swing Motor

Set Crossline Relief Valves

Swing Brake

Swing Drive

-SAW DRIVE

Felling Head, 20″ Saw. See Original Manufacturers Manual

Pressure Settings

Saw Circuit Description

Saw Circuit Schematic

Saw Control Valve

Saw Pump

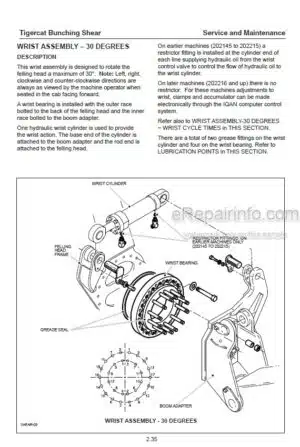

-TREE CLAMPS AND WRIST

Anti-Cavitation Relief Valve

Circuit Description

Circuit Schematic

Clamps And Wrist Control Valve

Pressure Settings

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet