Factory Service Manual For Tigercat Harvester. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 472

Number: 30938A (march 2012)

Bookmarks

Searchable

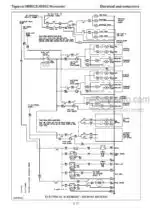

Wiring Diagrams

Hydraulic Diagrams

Model

Tigercat Harvester

H855C

LH855C

Contents

INTRODUCTION

STANDARDS TOPS, FOPS, OPS

NON-APPROVED FIELD PRODUCT CHANGES

-SAFETY

Battery Safety

Cab Exits

Cooling System

EC Declaration

Emergency Cab Exits

Engine Doors

ER Boom System Precautions

Exhaust Fumes

Fire Prevention

Fluid Injection Injury

Fluid Leaks

Grease Injection Injury

Harvesting Attachment – General Safety

Hazard Zone

Hydraulic Pressure Hazard

Lightning Safety Awareness

Lightning Safety

Loose Clothing Hazard

Machine Stability And Traction

Noise Level Inside Cab

Parking The Machine

Protective Clothing

Safety Interlock Switches On Cab Doors

Safety Labels

Safety Precautions, General

Safety Precautions, Operating

Safety Precautions, Servicing

Safety Symbols

Signal Words

Vibration Levels Inside Cab

Welding, Prior To

Working With Oil

-LUBRICATION & MAINTENANCE

Air Conditioning, Checking The System

Air Intake Maintenance

Air Precleaner

Case Drain Strainers

Checking The Air Conditioning System

Emergency Exits, Check Monthly

ER Boom System

Filters

Fire Prevention

Fuel Tank

Fuel Tank Shut-Off Valves

Hand Fill Pump, Hydraulic Oil

Hydraulic Oil Filters

Hydraulic Tank Pressurization Instructions

Lubrication Points Diagram Leveller

Lubrication Schedule

New Machine Maintenance

Oil Sampling Program

Pressure And Speed Settings

Preventive Maintenance Schedule

Scheduled Maintenance

Swing Drive Lubrication

Torque Chart, General

Torque, Fluid Connections

Track Components

-HYDRAULIC SYSTEM

Case Drain Strainers

Filters, Hydraulic Oil

Hydraulic Oil Tank

Hydraulic Pumps

Hydraulic System Operation

Load Sensing

Main Control Valve/Manifold

Schematic Diagrams

-PILOT SYSTEM

Accumulator

Circuit Description

Circuit Diagram

Electrical Circuit

Pilot System Components

Pilot System Schematic

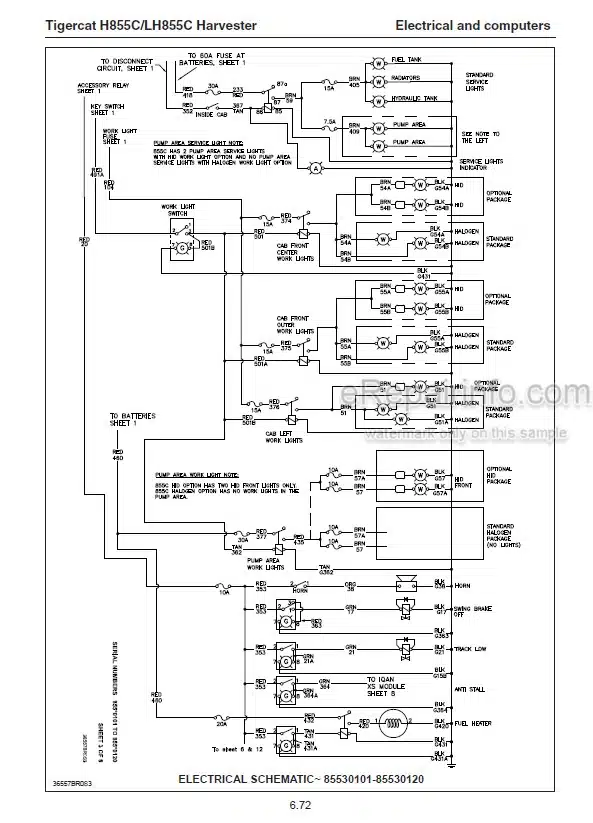

-ELECTRICAL AND COMPUTERS

Battery Compartment

Cab Module

Channels

Computer Control System (IQAN MDM Display)

Current Out – Troubleshooting For Open Circuits

Display Module

Downloading Applications From Dealer Website

Electrical Installation – Cab

Electrical Kit – Service And Diagnostics

Electrical Schematics

Engine Module

Error Messages And Alarms

Fault Codes : Error Messages

Fuses And Relays

Get Application

Get Error/Event Log

Id-Tag

IQAN

IQAN Software

Main System Errors

PDA Registration

Powerview Display Module

Switch And Sensor Locations

Update Application

Warm Up Mode

Wire Color Code Chart

-ENGINE START AND STOP

Cold Weather Starting

Engine, Restarting After Engine Run Out Of Fuel

Engine Starting

Engine, Stopping

Schematic Diagram

Starting Engine

Stopping Engine

Warm Up Mode

-ENGINE ANTI-STALL

Anti-Stall

-OIL COOLER, RADIATOR, CHARGE AIR COOLER AND FAN

Charge Air Cooler

Circuit Description

Circuit Diagram

Fan Circuit Hydraulic Schematic

Fan Drive Control Valve

Fan Drive Electrical Schematic

Fan Motor

Fan Pump

Fan Pump / (MAX) Maximum Pressure

Fan Pump / (POR) Pressure Override

Fan Speed Checks

Margin Pressure

Oil Cooler

Radiator

Radiator Cooling System

Standby Pressure

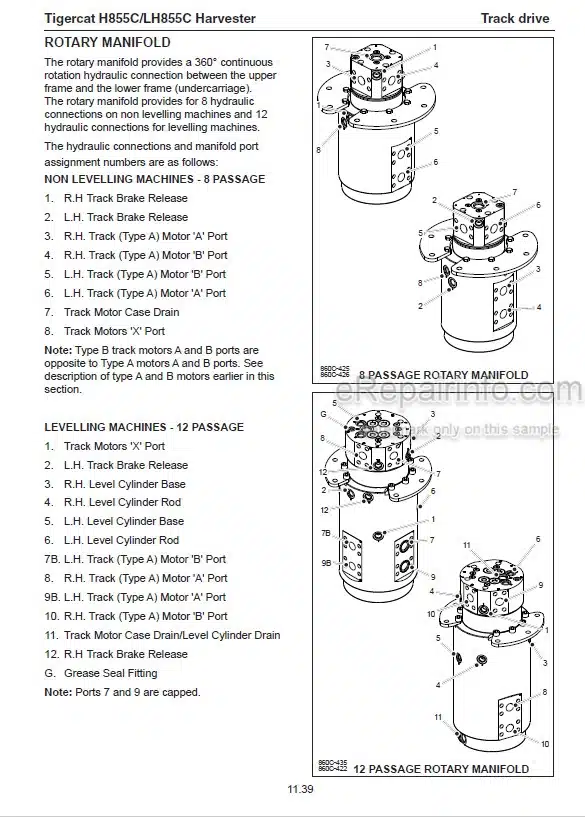

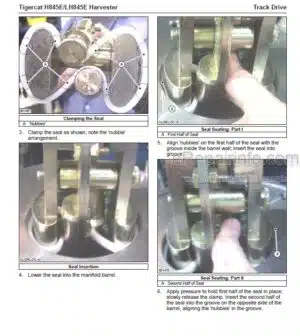

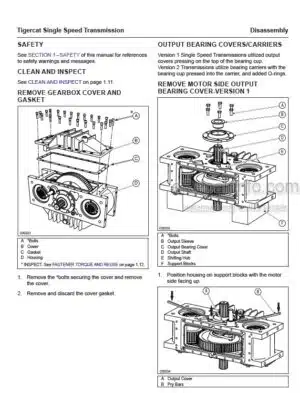

-TRACK DRIVE

Brake Circuit Description

Circuit Diagram, Drive System

Drive Motor

Drive Motor Type – Identification

Hydrostatic Drive System

Important Track Drive Notes

Left Track Speed Adjustment

Pressure Settings, Drive System

Right Track Speed Adjustment

Schematic Diagrams

Set Straight Travel

Track

Track Components

Track Drive Assembly

Track Speed Set-Up Procedure

Track Timing Chart

-BOOM FUNCTIONS

Adjust Oil Flow To Cylinders (Cylinder Cycle Times

Boom System Description

Circuit Diagram

Control Valve

Converting

Cylinder Cycle Times, Typical

ER Boom Manifold Connections

ER Boom System Components

ER Boom System – Service Position

ER Boom System – Service Safety

Load Sensing

See Also Section 9

Non-ER Boom Manifold Connections

Pressure Settings, Port Relief Valves

Schematic Diagrams

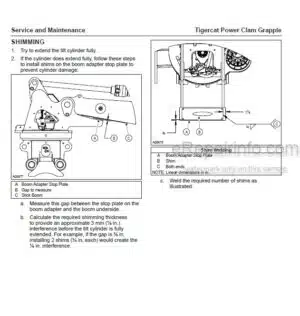

-LEVELLING

Checking Port Relief Valves

Circuit Description

Circuit Diagram

Circuit Hydraulic Schematic

Control Valve

Counterbalance Valve

Electrical Installation (Factory Installed)

Electronic Adjustment Procedure, Levelling

Engine Anti-Stall/Load Sensing

Hydraulic Tank Pressurization Instructions

Leveling Cylinder Taper Lock Pins

Levelling Circuit Description

Levelling Electronic Adjustment Procedure

Levelling System Description

Lubricating Cylinders And Pins

Lubrication Points Diagram Leveller

Replacing Port Reliefs

Scheduled Maintenance

Set Counterbalance Valve Pressures

Side Pivot Axis Bearing

Undercarriage Assembly, Levelling

-SWING

Adjust Oil Flow To Swing Motor(Swing Motor Speed)

Circuit Description

Circuit Diagram

Control Valve

Crossline Relief Valves

Main Control Valve

Pressure Settings

Schematic Diagrams

Set Swing Motor Speed

Swing Bearing

Swing Drive Gearbox

Swing Drive Lubrication

Swing Drive Valve Priority Circuit Description

Swing System Hydraulic Schematic

Swing Valve Schematic

-ATTACHMENT DRIVE

Attachment Control Valve, Pump 1

Circuit Description

Circuit Diagram

Electrical Schematic

Harvesting Head Installation

Hydraulic

Hydraulic Tank Pressurization Instructions

Main Control Valve, Pump 2

Main Pump (Pump 2)

Parking Head

Pressure Tests

Pump 2 Electronic Adjustment Procedure

Tilt Frame Lock Bolts

-HEAD ROTATE

Adjust Oil Flow To Head Rotate ( Cycle Times)

Circuit Description

Circuit Diagram

Control Valve

Head Rotate Circuit Description

Head Rotate Hydraulic Circuit

Load Sensing

Pressure Settings, Port Relief Valves

Setting Cycle Times

-TELESCOPIC BOOM

Circuit Description

Circuit Diagram

Computer Control System (IQAN MDM Display)

Control Valve

Main Pump

Pressure Settings, Port Relief Valves

Setting Cycle Times

Telescopic Boom Control Valve

Telescopic Boom Electronic Adjustment Procedure

-MISCELLANEOUS

Door Circuit – Electric Pump Operated System

Door Circuit – Engine Operated System

Door Switch

Electrical Schematic

Electric Power Engine Door Circuit Schematic

Electric Pump Operated System

Engine Operated System

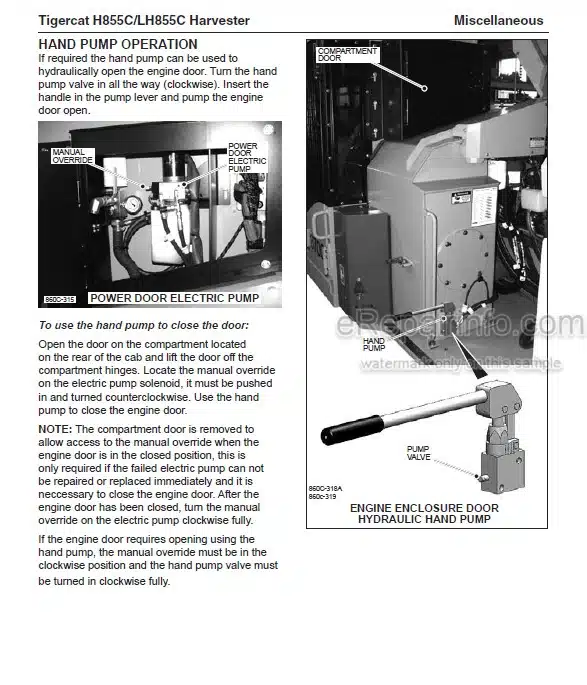

Hand Pump Operation

Instrument Panel Switch

Manual Override

Power Door

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet