Factory Operator And Service Manual For Tigercat Bunching And Felling Saws. Manual Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 208

Number: 8931A (july 2016)

Bookmarks

Searchable

Model

Tigercat Bunching And Felling Saws

Contents

INTRODUCTION

NON-APPROVED FIELD PRODUCT CHANGES

-SAFETY

Backover Accidents – Avoiding

Battery Disconnect Switch

Battery Safety

Cab Exits

Cable Assist

Cooling System

Diesel Exhaust Fluid (DEF)

During Operation

Emergency Cab Exits

Engine Doors

ER Boom Function, Switchable

ER Boom System Precautions

Exhaust Fumes

Felling Trees

Fire Prevention

Fluid Injection Injury

Fluid Leaks

General Safety Precautions

Grease Injection Injury

Hazard Zone

Hydraulic Pressure Hazard

Lightening Safety Awareness

Lightning Safety Awareness

Liquid Starting Aid

Loose Clothing Hazard

Machine Stability And Traction

Operating Safety Precautions

Parking Hazards

Parking The Machine

Pneumatic Grease Guns, Using

Pressurized Hydraulic Tank

Protective Equipment

Refueling

Safety Hazards – Operating

Safety Hazards – Viton Seals

Safety Precautions, General

Safety Precautions, Operating

Safety Precautions, Servicing

Safety Symbols

Seat Belt

Separation Distance

Servicing Safety Precautions

Signal Words

Viton Seals

Welding, Prior To

Working With Oil

-USING HIGH-SPEED DISC SAWS SAFELY

Comments And Instructions

Dangers

Foreword

High Angle Wrist Rotation Capability

Saw Head Donts

Type Of Housing Makes A Difference

-OPERATING, SERVICE AND MAINTENANCE

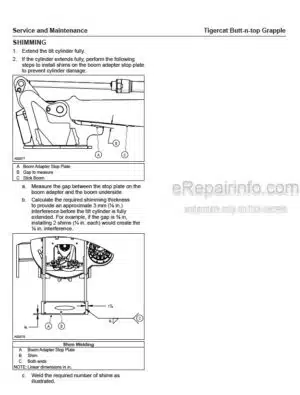

Butt Plate

Butt Plate And Pocket Floor Replace – Models 5000, 5400, 5500, 5600

Cylinder Seals

Felling Saw Part Names – Double Post

Felling Saw Part Names – Single Post

Felling Techniques

Initial Start-Up Of A New Saw Head

Lubrication Points

New Saw Maintenance

Operating Principal

Preventive Maintenance Schedule

Saw Blade

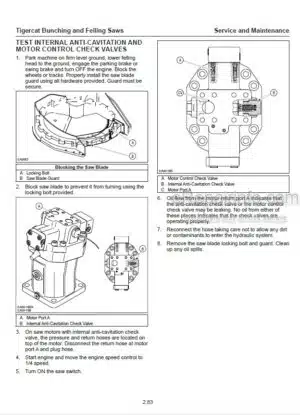

Saw Blade Guard And Locking Bolt

Saw Blade Lock Pin

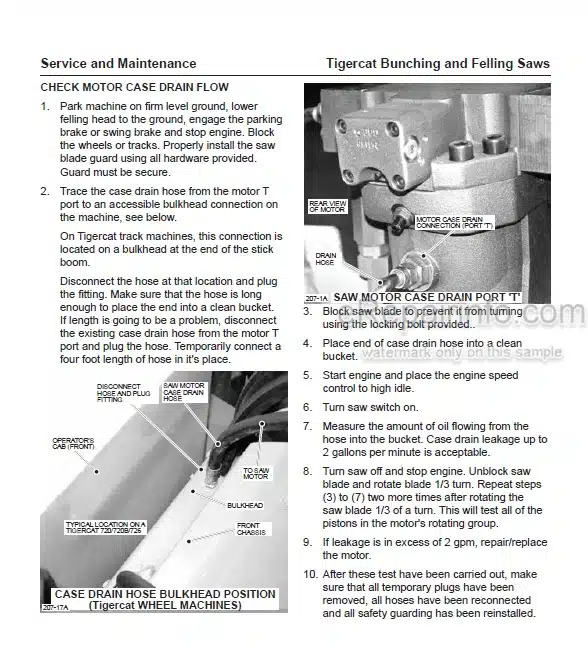

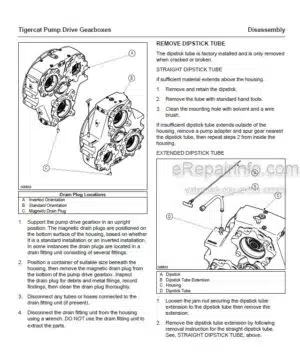

Saw Drive – Hydraulic

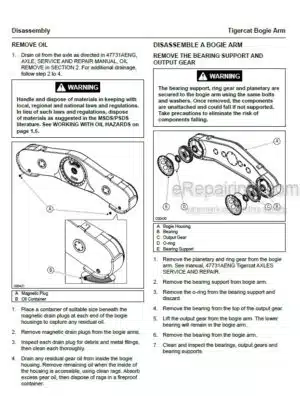

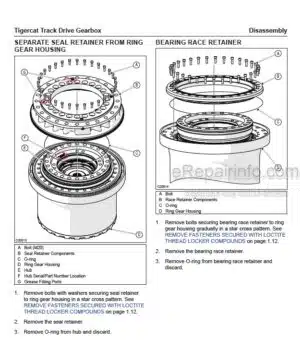

Saw Drive Spindle Components – Bolt On Spindle Drive Cap

Saw Drive Spindle Components – Threaded Spindle Locknut

Saw Drive Spindle End Play Description

Saw Drive Spindle Housing Temperature Check

Saw Housing Wear Liner

Saw Teeth

Scheduled Maintenance

Torque Chart

Torque Specifications – General

Troubleshooting Blade Speed

Wear Liner

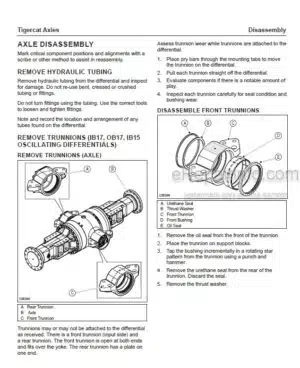

Wrist Assembly – 30°

Wrist Assembly – 110ª

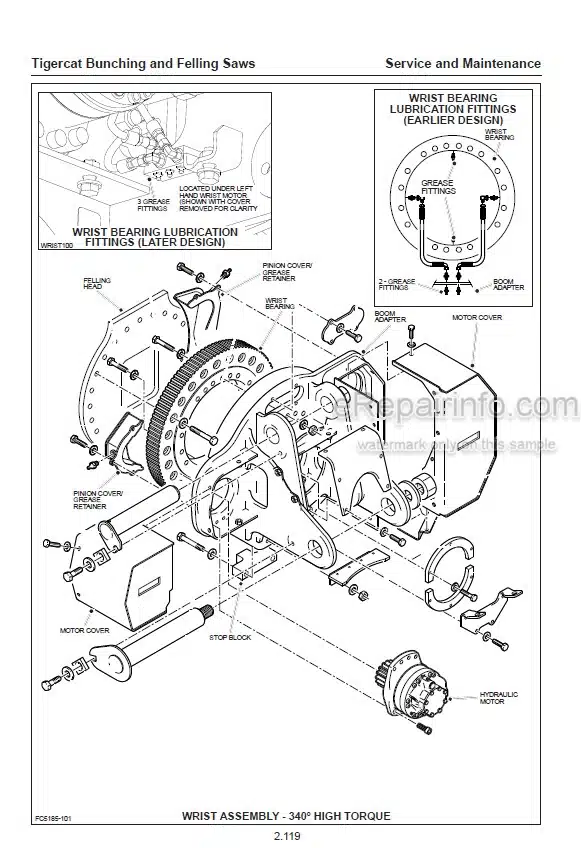

Wrist Assembly – 340° High Torque

Wrist Assembly – 340° Standard Torque

Wrist Bearing Seal Replacement

Wrist Bearing Wear Limits

Wrist Control Manifold

Wrist General Setup Procedure 340° Wrist

Wrist Troubleshooting

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet