Factory Operators Manual For Tigercat Loader. Manual For Owners And Operators. It Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Description Of Possible Faults / Problems And Their Solution.

Format: PDF

Language: English

Pages: 82

Number: 18878A (march 2004)

Bookmarks

Searchable

Model

Tigercat Loader

T250

Contents

INTRODUCTION

NON-APPROVED FIELD PRODUCT CHANGES

-SAFETY

Anti-Stall Control Module In Cab – Disconnect

Battery Disconnect Switch

Cooling System

Exhaust Fumes

Fire Prevention

First Aid

Fluid Leaks

Loose Clothing

Protective Clothing

Safety Precautions, General

Safety Precautions, Operating

Safety Precautions, Servicing

Safety Symbols

Understanding Signal Words

Welding, Prior To

-CONTROLS & OPERATION

Air Compressor/Vacuum Pump

Air Conditioner/Heater

Boom Controls

Cab Controls

Care Of The Machine

Cleaning Lexan Windows

Controls – Cab

Controls – Other

Delimber Arm Controls

Dimmer Control, Gauge Illumination

Engine Anti-Stall

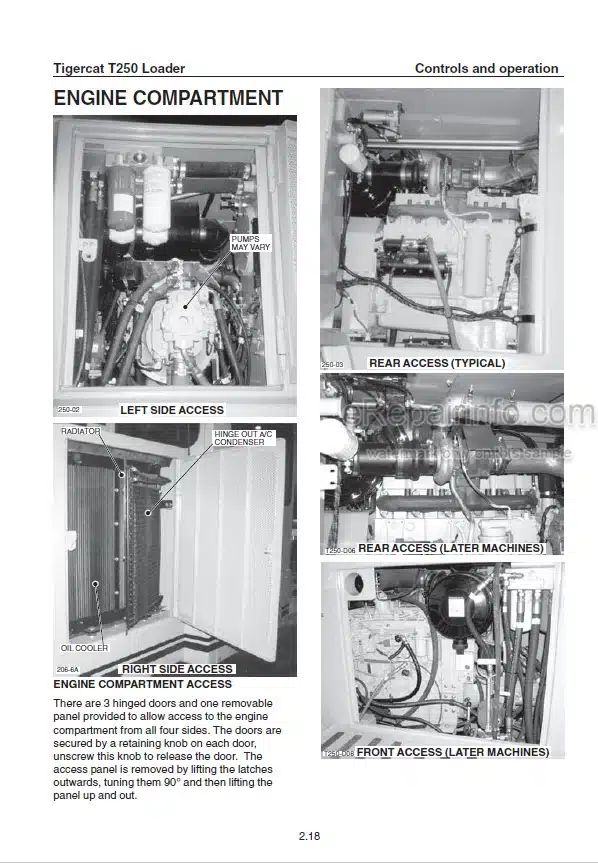

Engine Compartment

Engine Compartment Access

Engine, Hot Water Shut Off Valve

Engine, Starting

Engine Stopping

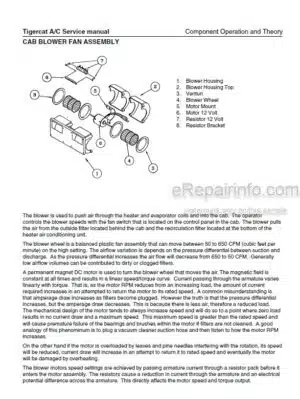

Fan, Cab

Filters

Filters, A/C And Heater

Filters, Cab Fresh Air

Filters, Hydraulic Oil, Pilot

Filters, Hydraulic Oil, Return

Fire Extinguisher

Fluid Leaks

Fuel Line Water Separator

Fuel Tank And Filler

Fuse And Relay Panel

Grapple Controls

Hand Fill Pump, Hydraulic Oil

Horn

Hot Water Shut Off Valve (Engine)

Hydraulic Oil Hand Fill Pump

Hydraulic Oil Reservoir

Hydraulic Oil Return Manifold

Hydraulic Pressurization System

Joystick, L.H.

Joystick, R.H.

Key Switch

Light-Dome

Machine Operation

Machine Preparation

Pilot Supply Shut Off Valve

Pressurization System, Hydraulic

Radio, 2-Way

Seat

Starting The Engine

Stopping The Engine

Swing Brake

Tape Deck

Vacuum Tank – Switch

Vacuum/Air Compressor Pump

Windows

-LUBRICATION & MAINTENANCE

Air Cleaner

Air Conditioning System

Air Intake Maintenance

Cycle Times, Cylinders, Factory Settings

Filters

Fire Prevention

General Maintenance

Hydraulic Oil Return Filters

Hydraulic Oils, Approved

Hydraulic Tank Pressurization System

Lubricating Cylinder Pins And Boom Joints

Lubrication Points

New Machine Maintenance

Oil Lost From Leakage Chart

Pilot Return Pressure Filter

Pressure Setting Procedures. See Service Manual

Pressure Settings, S/N 250T0111 To 250T0115

Pressure Settings, S/N 250T0131 And Up

Preventive Maintenance Schedule

Scheduled Maintenance

Service And Lubrication Points

Swing Drive Gearbox Lubrication

Torque Chart. General

Torque Settings, Recommended

Vacuum Pump (Later Design Only)

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet