Factory Repair Manual For Toyota Forklift. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 428

Number: CE 340-1

Searchable

Wiring Diagrams

Hydraulic Diagrams

Model

Toyota Forklift

7FBEST10

7FBEST13

7FBEST15

Contents

-GENERAL

Vehicle Exterior View

Vehicle Models

Frame Number

How To Use This Manual

Explanation Method

Disassembly – Inspection – Reassembly

Terminology

Abbreviations

SI Units

Operating Tips

General Instructions

Jack-Up Point

Lifting The Vehicle

Member Weights

Towing The Vehicle

Electrical Parts Inspection

Notes On SAS

Tightening Torque Table

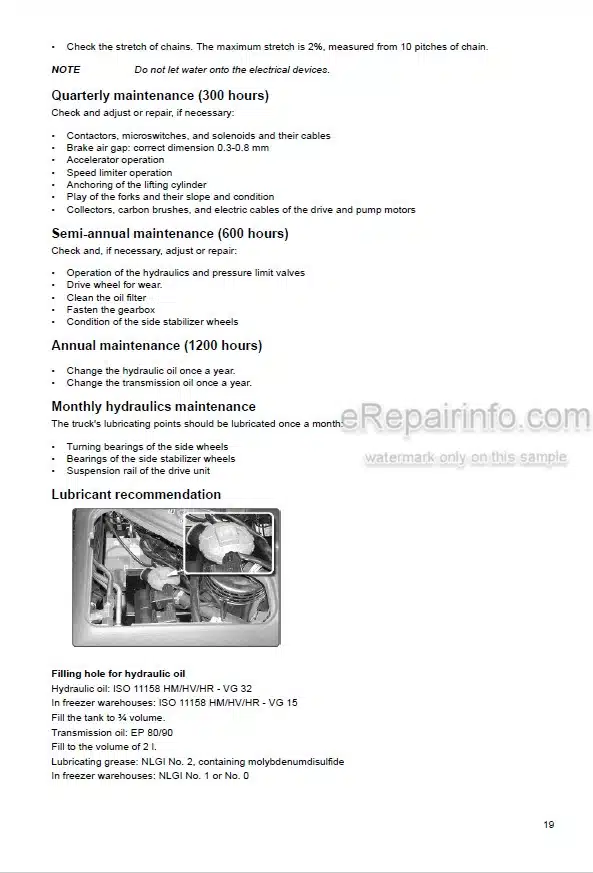

Recommended Lubricant Quantity And Types

Periodic Maintenance Table

Lubrification Chart

-BATTERY

Battery Compartment And Required Weight

Service Standards

Display

Battery Charge Indicator

Vehicle Behaviour With Discharged Battery

Vehicle Behaviour With Overdischarged Battery

Troubleshooting

Battery

Inspection

-CONTROLLER

General

Specifications

Components

Before Repair

Inspection

Connector Inspection

Traction Logic Unit

Pump Logic Unit

I/O Control Board

SAS Control Board

Minilever Mhyrio Board

Armrest Board

Controller

Traction & Pump Logic Unit

Operational Feature

Diagnosis

General Precautions

Protections

Minilever I/O Control Board (Mhyrio)

Armrest Board

I/O Control Board

Contactor Panel

Check Traction Motor Phases Balancing

Check Pump Motor Phases Balancing Measuring Method Procedure

Conctactor Panel Assembly Drawing

Display

Direction Switch

Accelerator Potentiometer Adjustment

Brake Switch Adjustment

-MULTI-DISPLAY FUNCTIONS

Multiple Display

General

Display And Buttons

Customer S Accessible Function

Turtle Function

P Special- Program Activation

P Special- Program Disabling

Mask Functions

Preparation For The Mask Menu Screen

Mask Function List

Password

Password Input Procedure

Operating Procedure

Category Modification

Classes Modification

Analyzer

Active Test

Tuning

Option

Matching

Alarms

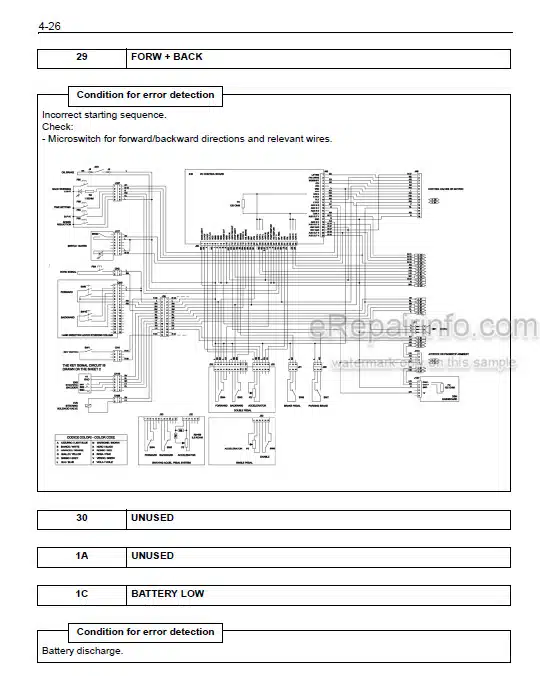

-TROUBLESHOOTING

Before Troubleshooting

Connector Handling

Wire Harness And Connector Inspection Procedure

System Configuration With Mechanic Control Valve

System Configuration With Electric Control Valve

Diagnosis Code List

When An Error Code Is Displayed

Traction Logic Unit

Pump Logic Unit

Minilever I/O Control Board (Mhyrio)

SAS Control Board

Armrest Board

Dashboard

I/O Control Board

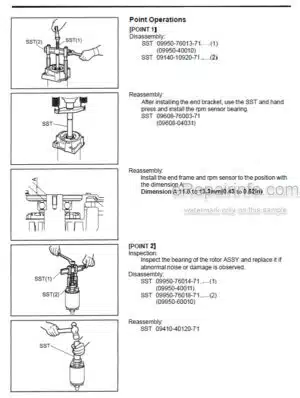

-MOTOR

Drive Motor

Point Operations

Pump Motor

Point Operation

-REAR AXLE

Rear Axle

Components

Steering Hydraulic Motor

Steering Potentiometer

Steering System

Hydraulic Motor

Steering Potentiometer

Rear Axle & Drive Unit

-STEERING

Power Steering System

Components

Hydrostatic Steering Valve

Troubleshooting

Power Steering

Point Operations

Inspect And Adjust The Relief Pressure

Priority Valve

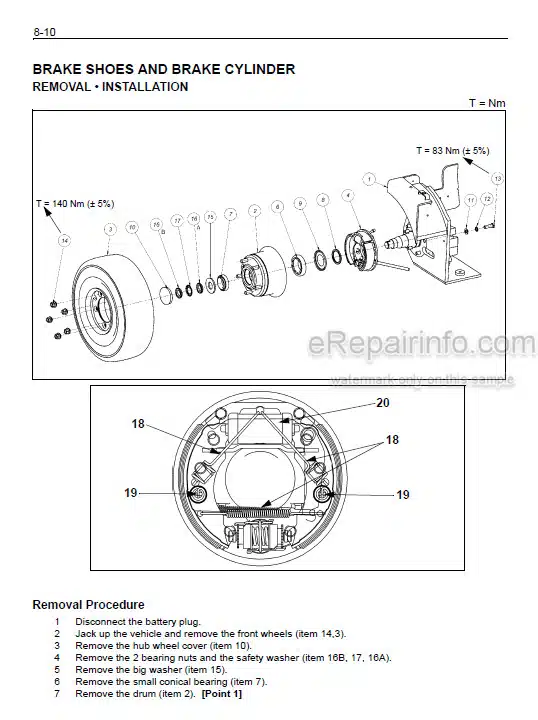

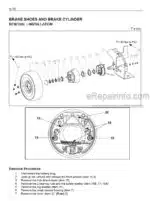

-BRAKE

Brake System

Parking Brake

Brake Pedal

Front Brake

Brake Group

Brake Shoes And Brake Cylinder

Point Operations

Brake Pedal

Brake Pedal Adjustment

Parking Brake

Point Operations

Parking Brake Adjustments

Adjustment

-BODY & FRAME

Components

Body & Frame

Battery Cover

Counterweight

Operator’S Seat

Fuses

Fuse Installation Locations

Names (Applicable Functions) And Capacities

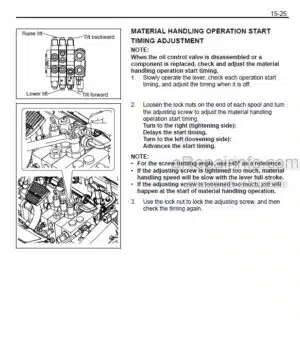

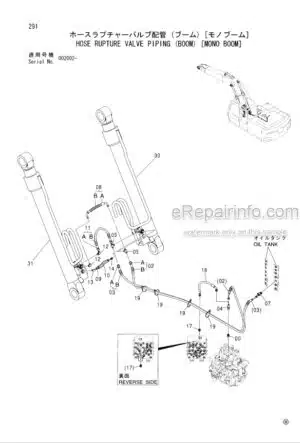

-MATERIAL HANDLING SYSTEM

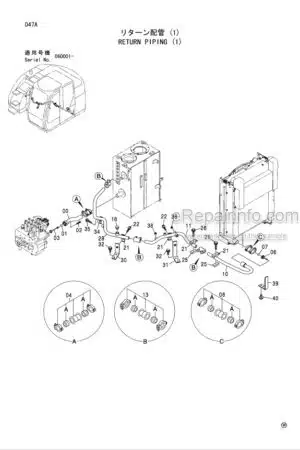

Hydraulic Circuit (Mechanic Control Valve)

Hydraulic Circuit (Electric Control Valve)

Components

Steering System

Hydraulic System (With Mechanic Control Valve)

Hydraulic System (With Electric Control Valve)

V Mast

FV Mast

FSV Mast

Hydraulic Oil And Filter

Point Operations

Natural Drop Test On Lifting

Natural Forward Tilting Test

Oil Leak Test

Lifting Cylinders

Tilting Cylinders

-MAST

V Mast

Components

Mast (V)

Fork Carriage

Chain And Chain Wheel

Point Operations

T And Fork Carriage Rollers (All Mast Types)

Point Operations

Mast And Fork Carriage Rollers (All Mast Types)

Mast Chains

Fork

FV – FSV Mast

Components Mast (FV)

Fork Carriage (FV – FSV)

Chain & Chain Wheel (FV)

Chain & Chain Wheel (FSV)

-CYLINDER

Lift Cylinder

General

Specifications

Side/Rear Lifting Cylinder (V And FSV)

Central Lifting Cylinder (FV And FSV)

Side/Rear Lifting Cylinder (FV)

Components

Lift Cylinder (V)

Side/Rear Lifting Cylinder (FV)

Side/Rear Lifting Cylinder (FSV)

Central Cylinder (FV And FSV)

Side/Rear Cylinder

Central Cylinder

Flow Regulator Valve (HAWE, For All Masts)

Specifications

Mast Performance Tables

Lifting

Tilting

Tilt Cylinder

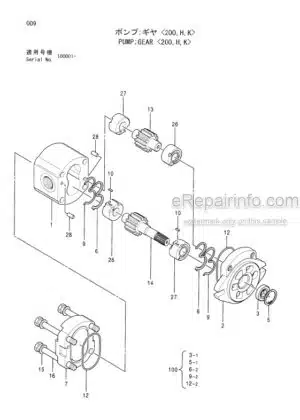

-OIL PUMP

Components

Service Pump

Test Method

Mast Performance Table (Lifting)

-OIL CONTROL VALVE

Mechanic Oil Control Valve

General

Oil Control Valve

Mechanic Oil Control Valve

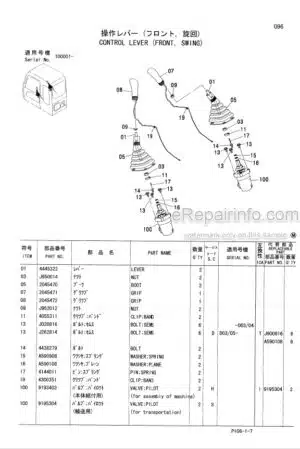

With Hand Direction Lever

Mechanic Oil Control Valve

With Hand Direction Lever

Hydraulic Diagram

Specifications

Mechanic Oil Control Valve

Point Operations

Maximum Pressure Valve Adjustment

Mast Performance Table

Lift Lock Unlocking Screw

Oil Control Valve Lever

Electric Oil Control Valve (For Minilever And Joysticks)

General

Oil Control Valve

Electric Oil Control Valve

Hydraulic Circuit Diagram

Specifications

Electric Oil Control Valve

Maximum Pressure Valve Adjustment

Mast Performance Table

Lift Lock Unlocking Screw

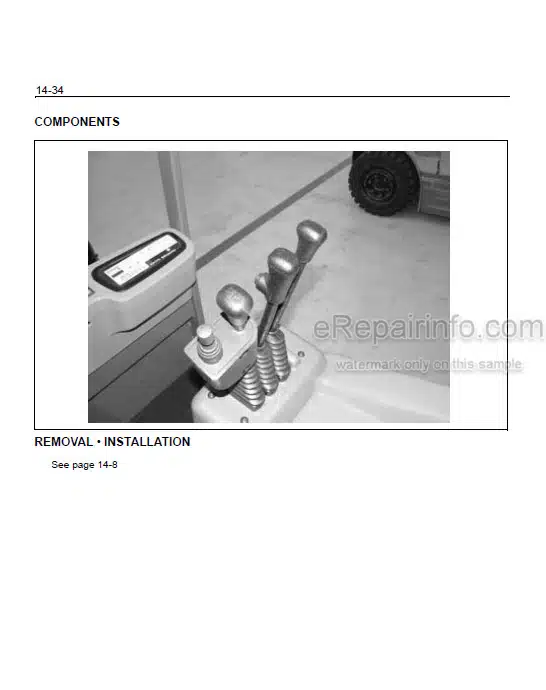

Minilever (Without And With Hand Direction Lever)

Components

Minilever (With Hand Direction Lever)

Joystick

-SAS FUNCTIONS

General

Components

For Repair Work

Steering Knob Synchronizer Valve

Tire Angle Sensor

Tilt Angle Sensor

Load Sensor

Mast Lifting Height Switch

Matching

Vehicle Standard State

Cautions On Modifying Vehicles

-APPENDIX

Load Sensor Wiring Harness

Mast Height Switch

Mast Wired Switch

Oil Control Valves Wiring Harness

Rear Window Heater Wiring Harness

Combi-Lights Wiring Harness

Rear Left Working Light Wiring Harness

Forward Working Lights Wiring Harness

Flashing Beacon Wiring Harness

Wired Buzzer 24 V

Seat Cable

I/O Control Unit

Lights Equipment Wiring Harness

3 Function Solenoid Valve Wiring Harness

4 Function Solenoid Valve Wiring Harness

Armrest Can-Bus Wiring Harness

Armrest Wiring Harness

SAS Group Wiring Harness

Wired Potentiometer

SAS Control Unit Group

Main Wiring Harness

Connectors

Ultrasonic Welding’s

Abbreviations

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet