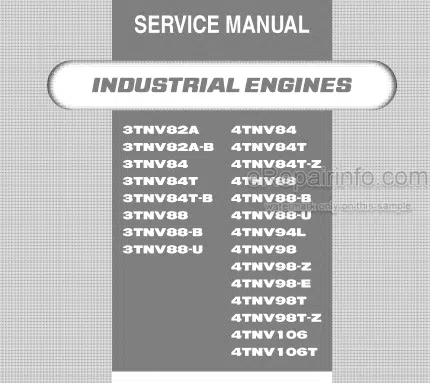

Factory Service Manual For Yanmar TNV82A To 3TNV88U 4TNV84 To 4TNV106T Industrial Engine. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 378

Bookmarks: Yes

Model

Yanmar 3TNV82A, 3TNV82A-B, 3TNV84, 3TNV84T, 3TNV84T-B, 3TNV88, 3TNV88-B, 3TNV88-U,4TNV84, 4TNV84T, 4TNV84T-Z, 4TNV88, 4TNV88-B, 4TNV88-U, 4TNV94L, 4TNV98, 4TNV98-Z, 4TNV98E, 4TNV98T, 4TNV98T-Z, 4TNV106, 4TNV1O6T

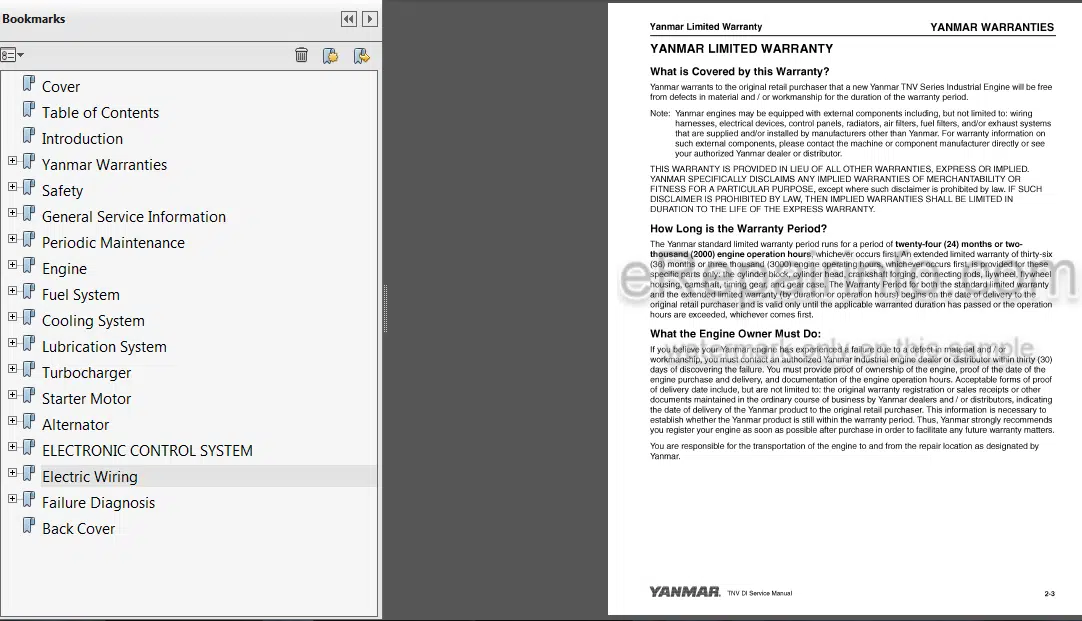

Contents

INTRODUCTION

-YANMAR WARRANTIES

–Yanmar Limited Warranty

What is Covered by this Warranty

How Long is the Warranty Period

What the Engine Owner Must Do

To Locate an Authorized Yanmar Industrial Engine Dealer or Distributor

What Yanmar Will Do

What is Not Covered by this Warranty

Warranty Limitations:

Warranty Modifications

Questions:

Retail Purchaser Registration

–Emission System Warranty

–Yanmar Co, Ltd Limited Emission Control System Warranty – USA Only

Your Warranty Rights and Obligations

Manufacturer’s Warranty Period

Warranty Coverage

Warranted Parts

Exclusions

Owner’s Warranty Responsibilities

-SAFETY

Safety Statements

Safety Precautions

-GENERAL SERVICE INFORMATION

Component Identification

Location of Labels

Engine Nameplate (Typical)

Emission Control Regulations

EPA/ARB Regulations – USA Only

Emission Control Labels

The 97/68/EC Directive Certified Engines

Engine Family

Function of Major Engine Components

–MAIN ELECTRONIC CONTROL COMPONENTS AND FEATURES

Function of Cooling System Components

Diesel Fuel

Diesel Fuel Specifications

Filling The Fuel Tank

Priming the Fuel System

Engine Oil

Engine Oil Specifications

Engine Oil Viscosity

Checking Engine Oil

Adding Engine Oil

Engine Oil Capacity (Typical)

Engine Coolant

Engine Coolant Specifications

Filling Radiator with Engine Coolant

Engine Coolant Capacity (Typical)

—Specifications

Description Of Model Number

Engine Speed Specifications

Engine General Specifications

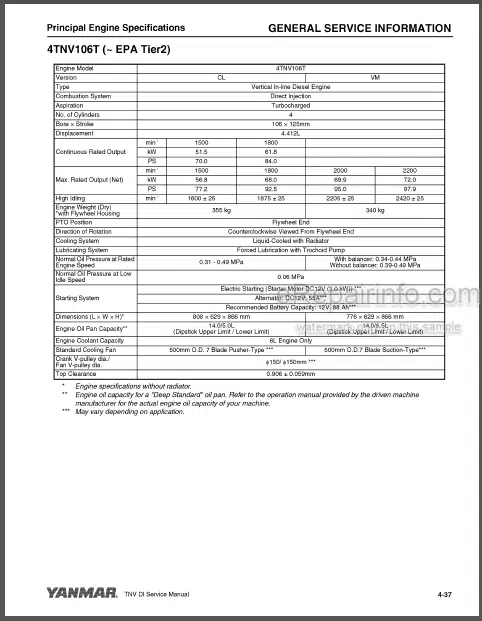

Principal Engine Specifications

3Tnv82A (Epatier2)

3Tnv84 (Epa Tier2)

3Tnv84T (Epa Tiei2)

3Tnv88 (Epa Tier2)

4Tnv84 (Epa Tier2)

4Tnv84T (Epa Tier2)

4Tnv88 (Epa Tier2)

4Tnv94L (Epa Tier2)

4Tnv98 (Epa Tier2)

4Tnv98T (Epa Tier2)

4Tnv106(Epa Tier2)

4Tnv106T (Epa Tier2)

3Tnv82A-B (Complies With Epa Interim Tier4)

3Tnv84T-Z (Complies With Epa Interim Tier4)

3Tnv84T-B (Complies With Epa Interim Tier4)

3Tnv88-Z (Complies With Epa Interim Tier4)

3Tnv88-U (Complies With Epa Interim Tier4)

3Tnv88-B (Complies With Epa Interim Tier4)

4Tnv84T-B 4Tnv84T-Z (Complies With Epa Interim Tier4)

4Tnv88-Z (Complies With Epa Interim Tier4)

4Tnv88-U (Complies With Epa Interim Tier4)

4Tnv88-B (Complies With Epa Interim Tier4)

4Tnv98-E (Complies With Epa Interim Tier4)

4Tnv98-Z (Complies With Epa Interim Tier4)

4Tnv98T-Z (Complies With Epa Interim Tier4)

Engine Service Standards

Tightening Torques for Standard Bolts and Nuts

—Abbreviations and Symbols

Abbreviations

Symbols

—Unit Conversions

Unit Prefixes

Units of Length

Units of Volume

Units of Mass

Units of Force

Units of Torque

Units of Pressure

Units of Power

Units of Temperature

-PERIODIC MAINTENANCE

Before You Begin Servicing

—Introduction

The Importance of Periodic Maintenance

Performing Periodic Maintenance

Yanmar Replacement Parts

Required EPA / ARB Maintenance -USA Only

EPA / ARB Installation Requirements – USA Only

—Periodic Maintenance Schedule

—Periodic Maintenance Procedures

After Initial 50 Hours of Operation

Every 50 Hours of Operation

Every 250 Hours of Operation

Every 500 Hours of Operation

Every 1000 Hours of Operation

Every 1500 Hours of Operation

Every 2000 Hours of Operation

Every 3000 Hours of Operation

-ENGINE

Before You Begin Servicing

Introduction

—Cylinder Head Specifications

Adjustment Specifications

Cylinder Head

Intake I Exhaust Valve and Guide

Push Rod

Rocker Ann and Shaft

Valve Spring

—Camshaft and Timing Gear Train Specifications

Camshaft

Idler Gear Shaft and Bushing

Timing Gear Backlash

—Crankshaft and Piston Specifications

Crankshaft

Thrust Bearing

Piston

Piston Ring

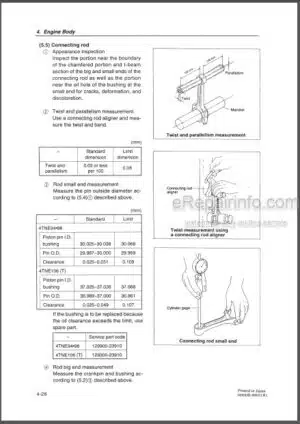

Connecting Rod

Tappet

—Cylinder Block Specifications

Cylinder Block

—Special Torque Chart

Torque for Bolts and Nuts

Special Service Tools

Measuring Instruments

2-Valve Cylinder Head

2-Valve Cylinder Head Components

Components Of A Two-Valve Cylinder Head

Disassembly Of 2-Valve Cylinder Head

Cleaning Of Cylinder Head Components

Inspection Of Cylinder Head Components

Reassembly Of Cylinder Head

—4-Valve Cylinder Head

4-Valve Cylinder Head Components

Disassembly Of 4-Valve Cylinder Head

Cleaning Of Cylinder Head Components

Inspection Of Cylinder Head Components

Reassembly Of Cylinder Head

—Measuring And Adjusting Valve Clearance

2-Valve Cylinder Heads

4-Valve Cylinder Heads

—Crankshaft And Camshaft Components

Disassembly Of Engine

Disassembly Of Camshaft And Timing Components

Disassembly Of Crankshaft And Piston Components

Inspection Of Crankshaft And Camshaft Components

Honing And Boring

Reassembly Of Crankshaft And Piston Components

Reassembly Of Camshaft And Timing Components

Final Reassembly Of Engine

—Egr System

Egr System

Egr System

Inspectingfcleaning Egr Related Components

-FUEL SYSTEM

Before You Begin Servicing

—introduction

Fuel Injection Pump

Stop Solenoid

Cold Start Device

Trochoid Fuel Pump

Electronically controlled governor

—Fuel System Specifications

Special Torque Chart

Test and Adjustment Specifications

—Special Service Tools

—Measuring Instruments

—Fuel System Diagram

—Fuel System Components

2-Valve Cylinder Head

4-Valve Cylinder Head

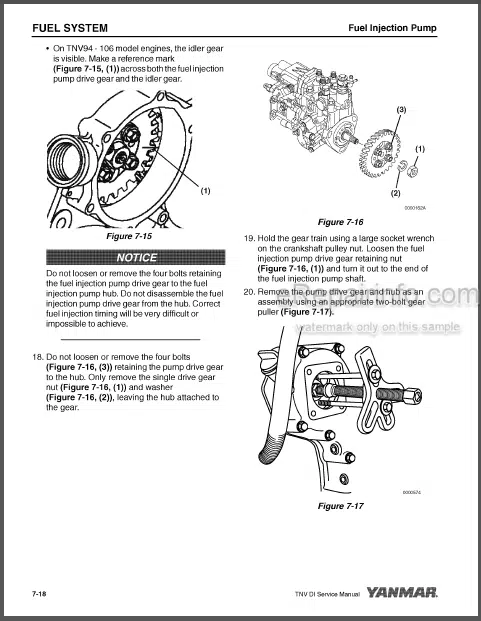

—Fuel Injection Pump

Removal of Fuel Injection Pump

Installation of Fuel Injection Pump

—Idle Sub Spring Adjustment

—Checking and Adjusting Fuel Injection Timing

Determining the Fuel Injection Timing Specification

Checking Fuel Injection Timing

Adjusting Fuel Injection Timing

—Fuel Injectors

Removal of Fuel Injectors

Testing of Fuel Injectors

Disassembly and Inspection of Fuel Injectors

Adjusting Fuel Injector Pressure

Reassembly of Fuel Injectors

Installation of the Fuel Injectors

-COOLING SYSTEM

Before You Begin Servicing

Introduction

Cooling System Diagram

Engine Coolant Pump Components

Engine Coolant System Check

—Engine Coolant Pump

Removal of Engine Coolant Pump

Disassembly of Engine Coolant Pump

Cleaning and Inspection

Reassembly of Engine Coolant Pump

Installation of Engine Coolant Pump

-LUBRICATION SYSTEM

Before You Begin Servicing

Introduction

Oil Pump Service Information

Lubrication System Diagram

Checking Engine Oil Pressure

—Trochoid Oil Pump

3TNV82A to 4TNV88 Oil Pump Components

Disassembly of Oil Pump

Cleaning and Inspection

Reassembly of Oil Pump

—Trochoid Oil Pump

3TNV82A-B 3TNV88-8, 3TNV88-U, 4TNV88-B4TNV88-U 3TNV84T-Z 4TNV84T-Z Oil Pump Components

Disassembly of Oil Pump

Cleaning and inspection

Reassembly of Oil Pump

—Trochoid Oil Pump

4TNV94L/98/106 Oil Pump Components

Disassembly of Oil Pump

Cleaning and Inspection

Reassembly of Oil Pump

-TURBOCHARGER

Before You Begin Servicing

Introduction

—Specifications

Turbocharger Service Information

—Troubleshooting

Excessive Exhaust Smoke

Generates White Smoke

Sudden Oil Decrease

Decrease in Output

Poor (Slow) Response (Starting) of Turbocharger

Abnormal Sound or Vibration

—Turbocharger Components

—Turbocharger Component Functions

Theory of Operation

Compressor Side Sealing Mechanism

Waste Gate Modulation

—Washing Procedure

—Periodic Inspection

Visual Inspection

Inspection of Rotor Rotation

Inspection of Rotor Play

Removal of Turbocharger

Checking Rotor Play

Waste Gate Valve Test

Waste Gate Actuator Leak Test

Installation of Turbocharger

-STARTER MOTOR

8efore You Begin Servicing

introduction

Starter Motor Information-3TNV82A to 4TNV88 – Standard and Optional

Starter Motor Specifications

Starter Motor Troubleshooting

Starter Motor Components

—Starter Motor

Removal of Starter Motor

Disassembly of Starter Motor

Cleaning and Inspection

Reassembly of Starter Motor

Check Pinion Projection Length

No-Load Test

Installation of Starter Motor

-ALTERNATOR

Before You Begin Servicing

introduction

Dynamo and Alternator Information

3TNV82A to 4TNV106T – Standard and Optional Dynamos-3TNV82A to4TNV106T – Standard and Optional Alternators

Alternator Specifications

Dynamo Specifications

Alternator T roubleshooting

Alternator Components

Alternator Wiring Diagram

Alternator Standard Output

—Alternator

Removal of Alternator

Disassembly of Alternator

Reassembly of Alternator

Installation of Alternator

—Dynamo Component Location

—Dynamo Wiring Diagram

—Operation of Dynamo

—Dynamo Standard Output

—Testing of Dynamo

Testing Stator Coil Continuity

Testing Stator Coil Short-to-Ground

Testing Dynamo Regulated Output

-ELECTRONIC CONTROL SYSTEM

Engines Available With The Electronic Control System

8Efore You 8Egin Servicing

Introduction

Electronic Control System

Electronic Control Harness Connections

-ELECTRIC WIRING

Electric Wiring Precautions

Electrical Wire Resistance

Battery Cable Resistance

Electrical Wire Sizes – Voltage Drop

Conversion of AWG to European Standards

-FAILURE DIAGNOSIS

Special Service Tools

Troubleshooting By Measuring Compression Pressure

Compression Pressure Measurement Method

Quick Reference Table For Troubleshooting

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet