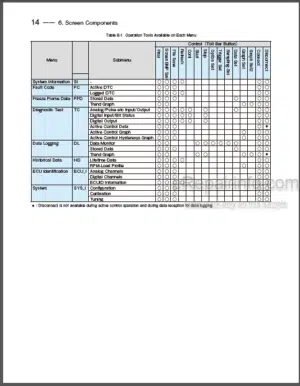

Factory Service Manual For Yanmar 4TNE94 4TNE98 4TNE106 Engine. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 174

Bookmarks: Yes

Model

Yanmar 4TNE94, 4TNE98, 4TNE106

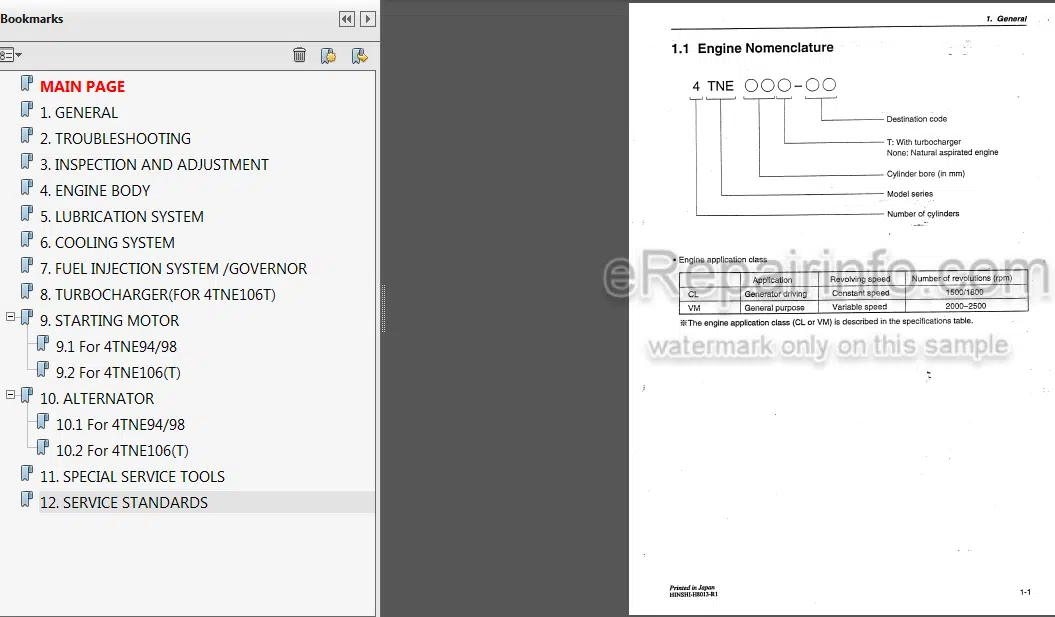

Contents

-GENERAL

ENGINE NOMENCLATURE

SPECIFICATIONS

FUEL OIL, LUBRICATING OIL

AND COOLING WATER

ENGINE EXTERNAL VIEWS

STRUCTURAL DESCRIPTION

–HOW TO READ THIS MANUAL

Range of Operation Explanation

How to Read The Explanations

Definition of Terms

Abbreviations

PRECAUTIONS FOR SERVICE WORK TIGHTENING TORQUES FOR

STANDARD BOLTS AND NUTS

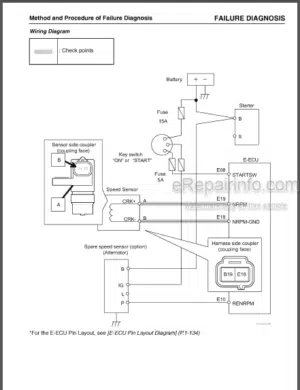

-TROUBLESHOOTING

QUICK REFERENCE TABLE FOR TROUBLESHOOTING

–TROUBLESHOOTING BY MEASURING COMPRESSION PRESSURE

Compression Pressure Measurement Method

Standard Compression Pressure

Engine Speed And Compression Pressure

Measured Value And Troubleshooting

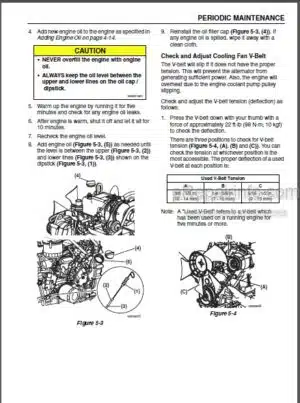

-INSPECTION AND ADJUSTMENT

Oil Inspection

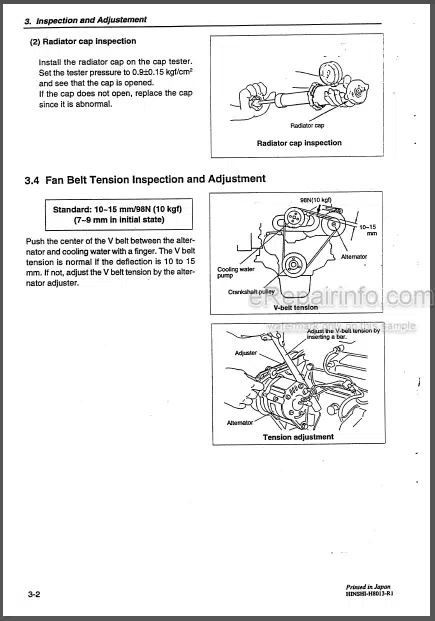

Cooling Water Inspection

Inspecting Water Leak From Cooling Water System And Radiator

Fan Belt Tension Inspection And

Adjustment

Adjusting The Valve Clearance

Inspecting The Fuel Injection Valve

Injection Pressure And Spray Pattern

Fuel Injection Timing Inspection And Adjustment

Adjusting The No-Load Maximum

(Or Minimum) Revolutions

Sensor Inspection

Battery Inspection

Adjusting Operation

Long Storage

Periodic Maintenance Schedule

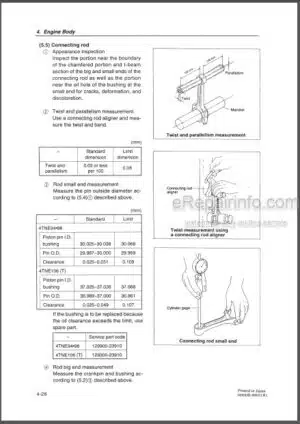

-ENGINE BODY

INTRODUCTION

–CYLINDER HEAD

Components

Disassembly Procedure

Reassembly Procedure

Servicing Points

Parts Inspection And Measurement

Valve Seat Correction

Valve Guide Replacement

Valve Stem Seal Replacement

–GEAR TRAIN AND CAMSHAFT

Components

Disassembly Procedure

Reassembly Procedure

Servicing Points

Parts Inspection And Measurement

Oil Seal Replacement

Camshaft Bushing Replacement

–CYLINDER BLOCK

Components

Disassembly Procedure

Reassembly Procedure

Servicing Points

Parts Inspection And Measurement

Cylinder Bore Correction

Piston Pin Bushing Replacement

Oil Seal Replacement

-LUBRICATION SYSTEM

Lubrication System Diagram

Trochoid Pump Components

Disassembly

Servicing Points

Parts Inspection And Measurement

-COOLING SYSTEM

-FUEL INJECTION SYSTEM /GOVERNOR

INTRODUCTION

–FUEL INJECTION PUMP

Fuel System Diagram

Components

Disassembly Procedure:

Assembly Procedure

Servicing Points

Parts Inspection And Measurement

FUEL INJECTION VALVE

–FUEL FEED PUMP

Components

Disassembly Procedure

Parts Inspection And Measurement

–GOVERNOR

Components

Disassembly Procedure

Parts Inspection And Measurement

SPECIAL SERVICE TOOLS FOR DISASSEMBLY/ASSEMBLY

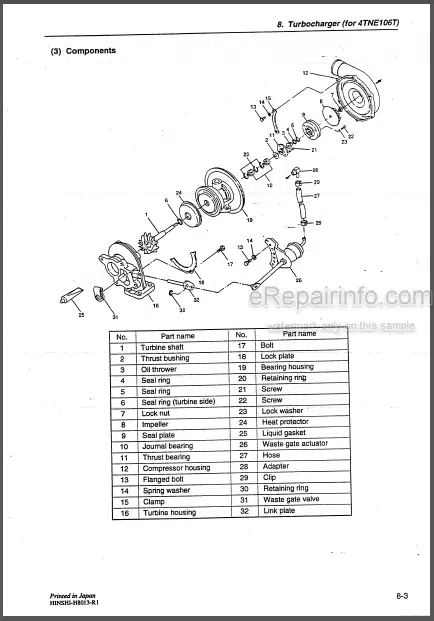

-TURBOCHARGER(FOR 4TNE106T)

–STRUCTURE AND FUNCTIONS

Structural and functional outline

Structure

Components

–SERVICE STANDARDS

Service Standards

Tightening Torque

–PERIODIC INSPECTION PROCEDURE

Periodic Inspection Intervals

Inspection Procedure

Waste Gate Valve Adjustment Procedure

–DISASSEMBLY PROCEDURE

Preparation For Disassembly

Inspection Before Disassembly

Disassembly

–WASHING AND INSPECTION PROCEDURE

Washing

Inspection procedure

–REASSEMBLY PROCEDURE

Preparation For Reassembly

Reassembly

HANDLING AFTER DISASSEMBLY AND REASSEMBLY

TROUBLESHOOTING

-STARTING MOTOR

–For4TNE94/98

Specifications

Components

Troubleshooting

Names Of Parts And Disassembly Procedure

—Inspection And Maintenance

Armature

Field Coil

Brush

Brush Holder

Magnetic switch

Pinion Clutch

Service Standards

Assembly

Characteristic Test

–

–For 4TNE106(T)

Specifications

Configuration Drawing

Troubleshooting

Component Names and Disassembly Procedure

Disassembly Procedure

-ALTERNATOR

–For4TNE94/98

Specifications

Sectional View

Troubleshooting

Parts Names And Disassembly Procedure

—Inspection And Overhaul

Diode

Rotor

Stator

Brush

Check Of 1C Regulator

Assembly

Service Standards

Performance Test

–For 4TNE106(T)

Specifications

Exploded View

Troubleshooting

Disassembly Procedure

Inspection and Maintenance

Reassembly Procedure

Performance Test

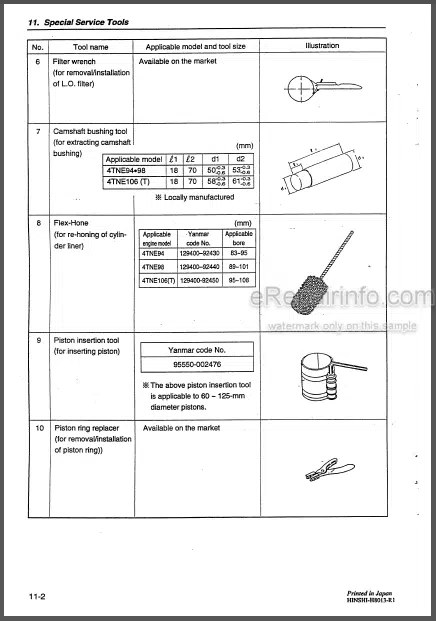

-SPECIAL SERVICE TOOLS

Special Tools

Measuring Instruments

-SERVICE STANDARDS

What you get

You will receive a PDF file with a high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet