Factory Service Training For Bomag —-. The Bomag Service Training Manual Describes The Disassembly, Dismantling, Assembly, Installation And Repair Of Components And Assemblies. Manual Addresses The Professionally Qualified Personnel Or The After Sales Service Of Bomag, And Should Be Of Help And Assistance In Correct And Efficient Repair And Maintenance Work.

Format: PDF

Language: English

Pages: 700

Number: 00891992 (february 2013)

Bookmarks: Yes

Searchable: Yes

Wiring Diagram: Yes

Hydraulic Diagram: Yes

Model

Bomag Road Finisher

BF800C

S/N 821 837 17 1001 ….

S/N 821 837 71 1001 ….

S/N 821 837 19 1001 ….

S/N 821 837 66 1001 ….

Contents

-GENERAL

Introduction

Safety Regulations

General Repair Instructions

Tightening Torques

-TECHNICAL DATA

Technical Data

-MAINTENANCE

General Notes On Maintenance

Fuels And Lubricants

Table Of Fuels And Lubricants

Running-In Instructions

Maintenance Table

-E-PLAN WIRING DIAGRAMS

General Notes On Maintenance

Fuels And Lubricants

Table Of Fuels And Lubricants

Running-In Instructions

Maintenance Table

-ENGINE

Diesel Engine

Engine Description TCD 2012

Lubrication Oil Circuit TCD 2012/2013

Coolant Circuit TCD 2012 / 2013

Fuel System TCD 2012 / 2013

Deutz Common Rail (DCR) Injection System For TCD 2012 / 2013

Exhaust Gas Recirculation TCD 2012 / 2013

Wastegate – Charge Pressure Controller On TCD-Engines

Engine Problems

Checking The Engine Oil Level

Changing Engine Oil And Oil Filter Cartridge

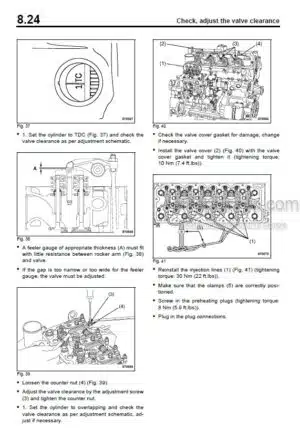

Replacing The Fuel Pre-Filter Cartridge, Bleed The Fuel System

Replace The Fuel Filter

Check, Clean The Water Separator

Check The Coolant Level

Replace The Coolant

Checking The Thermostat In Disassembled State

Air Filter Maintenance

Clean The Cooling Fins On Engine And Hydraulic Oil Cooler

Intercooler, Drain Off Oil And Condensation Water

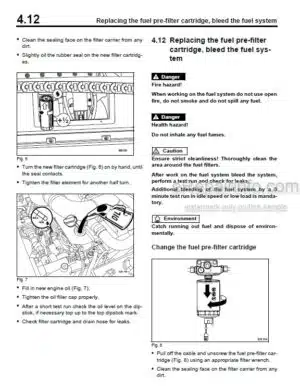

Adjust The Valve Clearance

Checking The Ribbed V-Belt, Replacing If Necessary

Replace The Crank Case Ventilation Valve

Engine Conservation

Special Tools, Deutz Engine (TCD 2012 2V)

-ENGINE ELECTRICS

EMR3 System Components

Deutz EMR3 – Engine Connections

Pin Assignment Of Engine Control EDC16 / EMR3

Rotary Speed Sensor For Camshaft

Crankshaft Speed Sensor

Rail Pressure Sensor

Fuel Pressure Sensor

Fuel Control Unit

Injector

Oil Pressure Sensor

Sensor For Charge Air Temperature And Charge Air Pressure

EMR Coolant Temperature Sensor

Glow Plugs

Sensor, Water In Fuel

Air Filter Vacuum Switch

Float Switch, Coolant Tank

Charge Control Light, Engine Rpm-Meter

Diagnose With Serdia

Diagnose With Can-Bus

Diagnostics Interface

Emr3 List Of Fault Codes

Generator

Replacing The Voltage Regulator

Electric Starter

-ELECTRICS

Service The Battery, Check The Main Battery Switch

Starting The Engine With Jump Leads

Starting With Jump Wires

Fuses

Fuse Assignment

Component Overview – Electrics

Overview Of Wiring Looms

Control Elements

View Of Control Panel

Instrument Cluster

Data Collector

View Of External Operator Stations

View Of External Operator Stations

View Of Screed Control Panel

View Of Electric Heating Control Panel

Functional Block Diagram Overview Of Functions, Complete

Block Diagram Components On Can

Block Diagram Can With Control Elements

Block Diagram Of Travel Circuit

Block Diagram Material Feed

Block Diagram Screed

Block Diagram Screed Heating

Functional Block Diagram Monitoring Functions

Block Diagram Emergency Stop Functions

Electronic Control Units

Checking The Voltage Supply For The Control Unit

Diagnostics Concept

-ERROR CODES — GENERAL INFORMATION

Error Codes – BF800 – General Information

-INPUT CODES

Input Codes

-REPLACEMENT OF COMPONENTS

How To Proceed When Replacing Components

-MATERIAL HOPPER, DESCRIPTION

Material Hopper And Transport

-VIBRATING SCREED, DESCRIPTION

Screed

-BASIC SETTINGS ON THE SCREED

Notes On The Screed Adjustment (Type S500 & S600)

Bringing The Straight Crossfalls To Zero Position

Aligning Basic Screed And Mobile Sections

-ASSEMBLING THE SCREED EXTENSIONS

Notes On Assembling Screed Extensions

Assembling The Screed Extensions

-ELECTRIC SCREED HEATING, REPAIR

Electric Screed Heating

Electric Screed Heating – Commissioning

Faults In The Electric Heating

-TRAVEL DRIVE, DESCRIPTION

Travel System

-HYDRAULICS

Hydraulic Circuit

Component Overview – Hydraulics

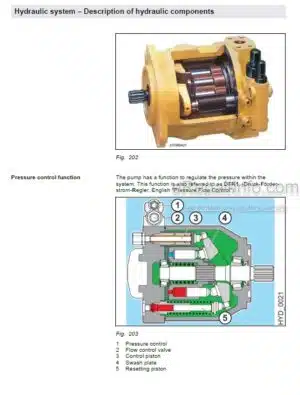

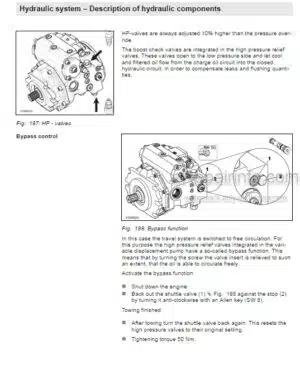

Description Of Travel Pump

View Of The Machine

Pumps For: Scraper Belt, Augers, Vibration & Tampers

View Of The Machine

Description Of Fan Pump

View Of The Machine

Description Of Charge Pumps

Check The Hydraulic Oil Level

Change Hydraulic Oil And Hydraulic Oil Filter

-HYDRAULICS – TRAVEL CIRCUIT

Description Of Driving

Description Of Brake Circuit

-HYDRAULICS – MATERIAL TRANSPORT

Description Of Scraper Belts

Description Of Augers

Description Tamping

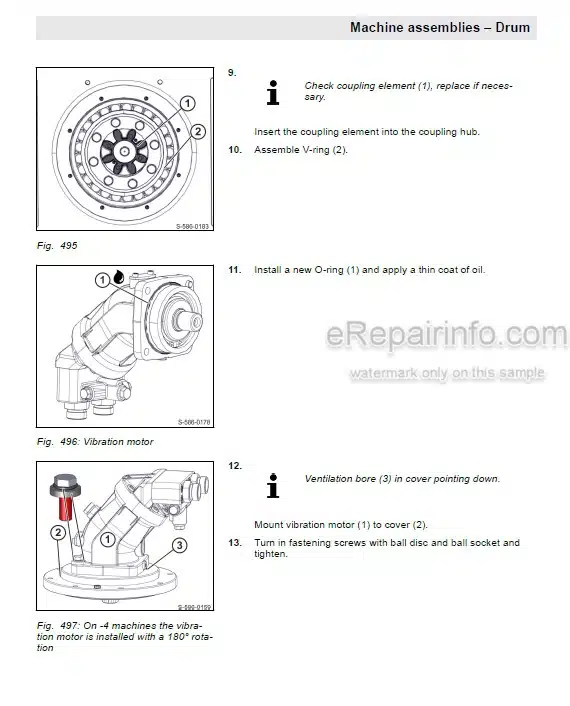

Description Vibration

-HYDRAULICS – SERVICE

Description Of Fan Circuit

Description Of Service (A)

Description Of Service (B)

Description Of Load Control System (LCS)

-TESTS AND ADJUSTMENTS

Special Tools, Tests And Adjustments

Checking And Adjusting The Vibration

Checking/Adjusting Tamping

Checking/Adjusting The Scraper Belts

Checking/Adjusting The Augers

Checking & Adjusting The Service Pump/Cylinder Functions

Checking & Adjusting The Time For Screed Levelling

Checking/Adjusting The Hopper Wings

Checking/Adjusting The Mobile Screed

-CIRCUIT DIAGRAMS

Hydraulic Diagram

Electric Circuit Diagrams

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet