New Holland LS180 LS190 Repair Manual

Overview

The New Holland LS180 and LS190 Skid Steer Loader Repair Manual is a comprehensive, factory-issued guide designed to facilitate the maintenance, service, and repair of these models. This manual provides detailed illustrations, step-by-step instructions, and precise diagrams, making it an invaluable resource for technicians and operators. It includes two versions of the manual to cover all aspects of repair and maintenance thoroughly.

Key Features

- Format: PDF

- Language: English

- Pages: 911 and 948

- Bookmarks: Yes

- Searchable: Yes

- Wiring Diagrams: Yes

- Hydraulic Diagrams: Yes

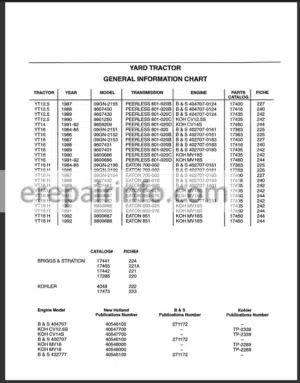

Applicable Models

- New Holland LS180 (Model: 332T/JF)

- New Holland LS190 (Model: 450/NC)

Content Structure

This repair manual is meticulously organized into several comprehensive sections, covering all critical components and systems of the New Holland LS180 and LS190 Skid Steer Loaders. The contents include:

General Information

- Introduction: Overview of the manual and its usage.

- About Improvements: Information on machine updates and improvements.

- Company Policy: Guidelines and policies.

- Parts And Accessories: Details on parts and accessories.

- Model Codes: Explanation of model codes.

- Precautionary Statements: Important safety statements.

- Safety Precaution Information: Comprehensive safety guidelines.

- General Safety Information: Additional safety measures.

- Machine Model And Serial Number Location: Identification of machine model and serial numbers.

- Engine Model And Serial Number Location: Identification of engine model and serial numbers.

- Hardware Torque Specifications: Torque specifications for hardware.

- Installation Of Adjustable Fittings In Straight Thread O-Ring Bosses: Procedures for fitting installation.

- Standard Torque Data For Hydraulic Tubes And Fittings: Torque specifications for hydraulic components.

- Pipe Thread Fitting Torque: Torque specifications for pipe thread fittings.

- Lubricants And Coolants: Recommended lubricants and coolants.

- Sealants: Information on sealants used in maintenance.

Engine

- Introduction: Overview of engine-related sections.

- Safety Precautions: Engine-specific safety guidelines.

- Engine Services: Detailed engine services procedures.

- Engine Model And Serial Number Location: Identification of engine components.

- General Engine Specifications Service Standards: Engine specifications and service standards.

- Hardware Torque Chart: Torque specifications for engine hardware.

- Torque Specifications: Detailed torque specifications.

- Timing Gear and Engine Timing: Procedures for timing gear and engine timing.

- Cooling System and Thermostat: Maintenance and troubleshooting for cooling system and thermostat.

- Starting A Turbocharged Engine After Installation Of A Turbocharger: Guidelines for starting a turbocharged engine.

- Engine Installation and Operating The Engine After Overhaul: Procedures for engine installation and operation post-overhaul.

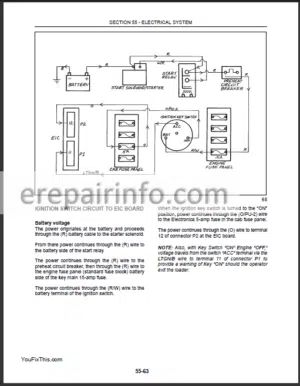

- Electrical Component Maintenance and Adjust Belt Tension: Maintenance of electrical components and belt tension adjustments.

Rear Drive Axle (Gearboxes)

- Gearboxes: Maintenance and repair of gearboxes.

- Final Drive And Gearbox Fill/Check Plug: Procedures for final drive and gearbox maintenance.

- Gearbox Parts and Reinstallation: Detailed parts list and reinstallation procedures.

- Engine To Transmission: Connection procedures between engine and transmission.

Hydrostatic Transmission

- Low Power Through The Engine/Transmission System: Troubleshooting low power issues.

- Hydrostatic Drive System Testing and Oil Flow: Testing procedures and oil flow details.

- Hydrostatic Charge System Pressure Test: Pressure testing procedures.

- Hydrostatic Pump and Motor Tests: Detailed testing procedures for pumps and motors.

- Hydraulic, Hydrostatic System Air Ingress Test: Testing for air ingress.

- Hydrostatic And Charge Pumps: Maintenance and repair of pumps.

- Hydrostatic Pump Parts and Motors: Detailed parts list and motor maintenance.

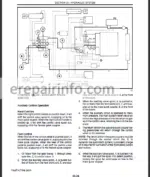

- Steering System: Maintenance and troubleshooting for the steering system.

- Hydrostatic System Controls and Neutralizer Assembly: Control system and neutralizer assembly procedures.

- Control Linkage and High/Low Range Adjustment: Linkage adjustments and range settings.

Brakes And Controls

- Detailed procedures for maintaining and troubleshooting brakes and control systems.

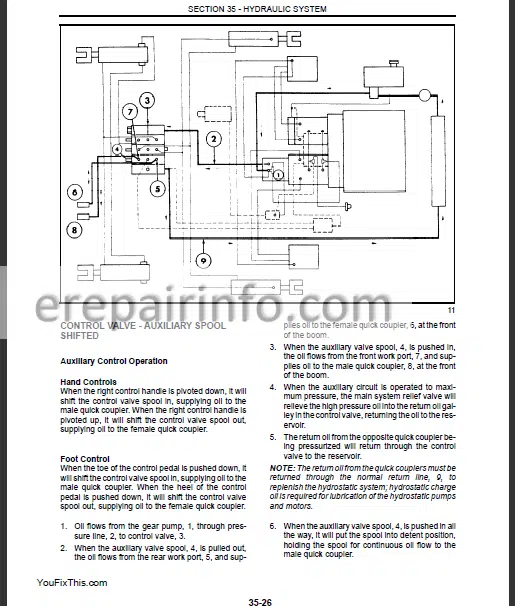

Hydraulic System

- Boom Cylinder Pivot Pins: Maintenance and troubleshooting for hydraulic system components.

Utility

This repair manual is indispensable for technicians, operators, and anyone involved in the maintenance and repair of the New Holland LS180 and LS190 Skid Steer Loaders. It provides comprehensive information to perform routine service, identify and solve issues, and execute complex repair tasks. The manual’s structured format, extensive diagrams, and step-by-step instructions ensure that all maintenance and repair procedures are executed accurately and efficiently.

Accessibility

The PDF format of the manual, complete with bookmarks and searchable text, allows users to quickly locate specific sections and information. Detailed wiring and hydraulic diagrams enhance the manual’s utility, providing clear and precise guidance for resolving electrical and hydraulic system issues.

By utilizing this repair manual, you can ensure the high performance and reliability of your New Holland LS180 and LS190 Skid Steer Loaders, supporting best practices in maintenance and repair to keep your equipment in optimal condition.

Anonymous (verified owner) –

Received it very quickly and a person is actually able to read it. Will definitely use your services again.